What is Precision Manufacturing?

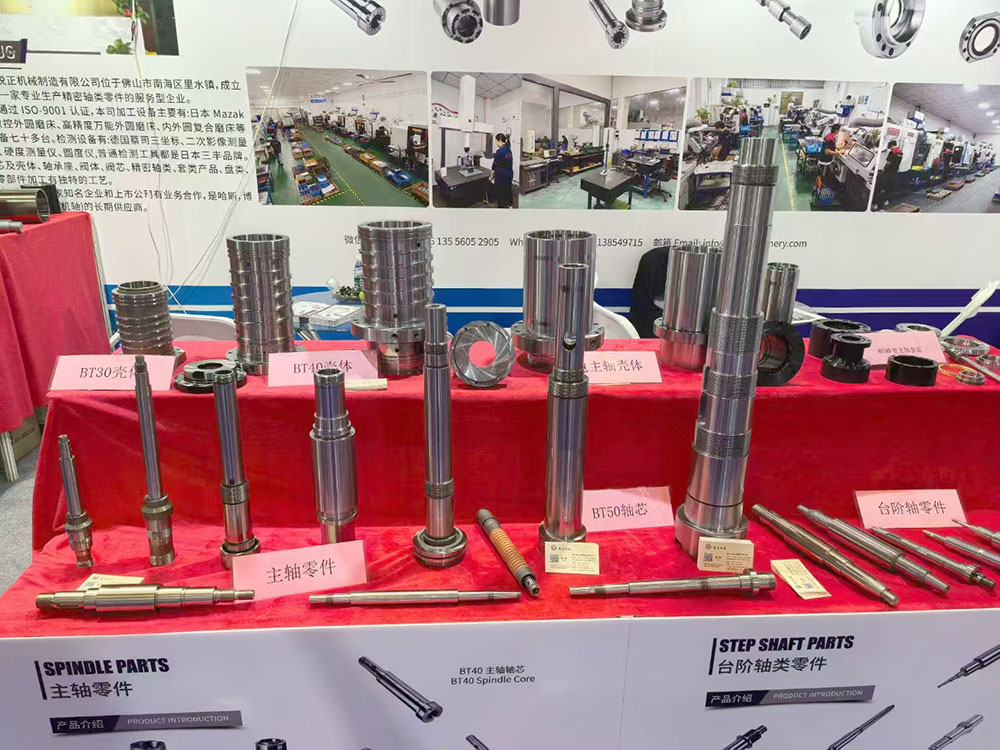

Precision Manufacturing is a manufacturing model that uses high-precision equipment, advanced processes and digital control technology to produce parts or products within micron or even nanometer error ranges. Its core goal is to ensure absolute consistency in product quality while improving production efficiency and reducing material waste. In the era of Industry 4.0, precision manufacturing combined with artificial intelligence, the Internet of Things (IoT) and automation technology has become the core driving force for the upgrading of the manufacturing industry.

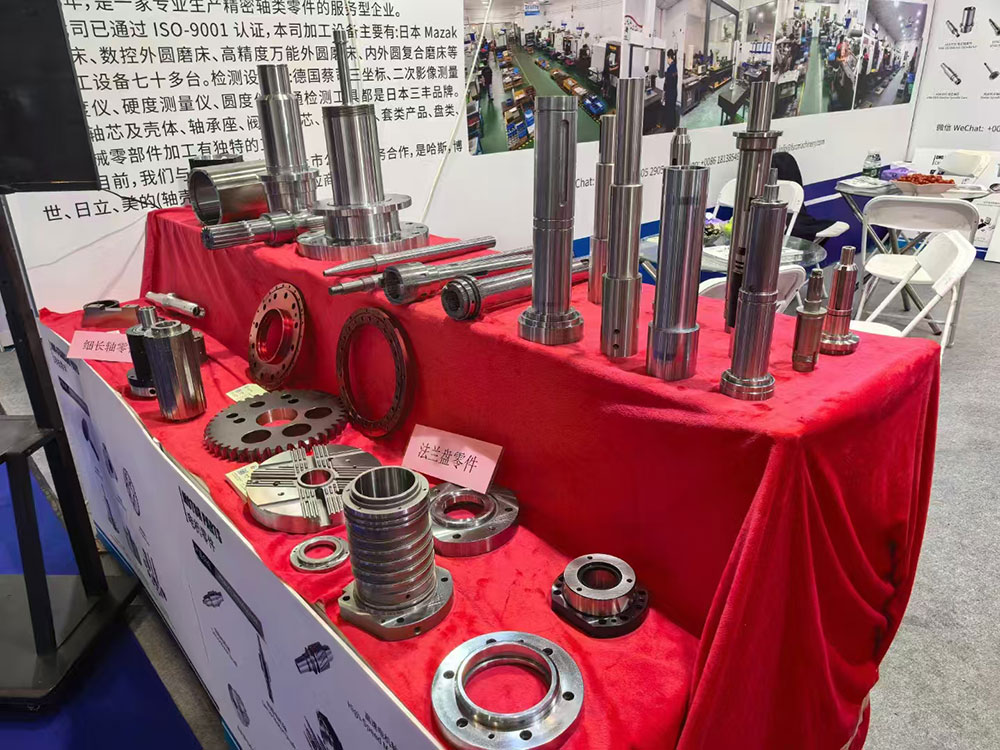

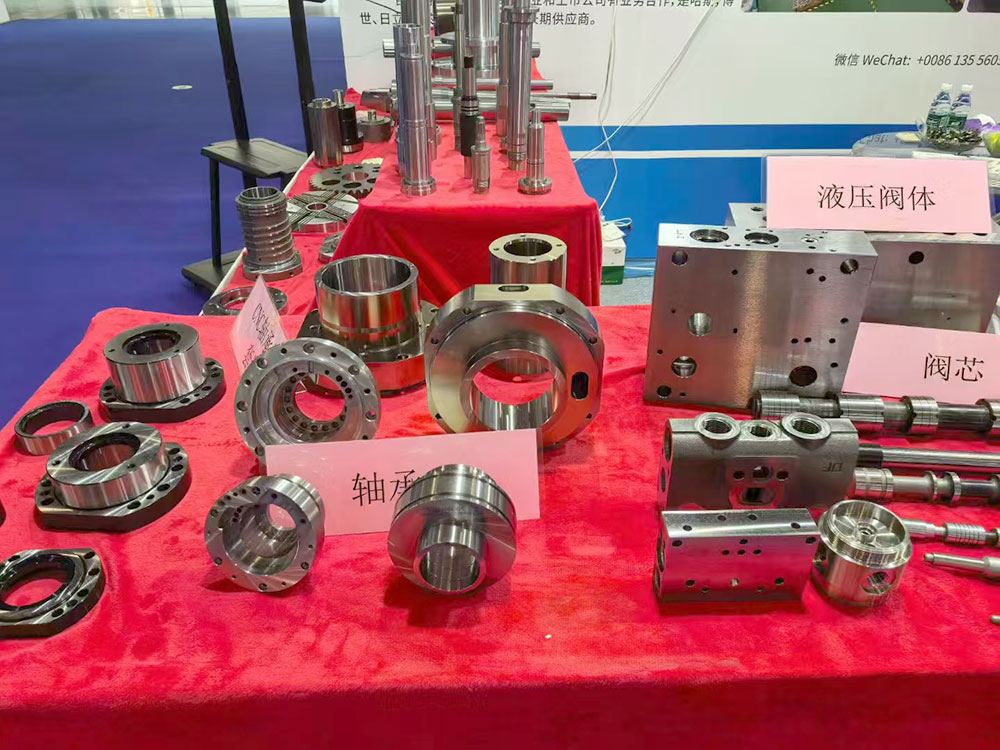

Compared with traditional manufacturing, precision manufacturing pays more attention to detail control, such as the use of five-axis CNC machine tools (CNC), laser cutting, 3D printing and other technologies to ensure the precise molding of complex geometric shapes. This technology is not only suitable for metal processing, but also widely used in diversified material fields such as ceramics, composite materials, semiconductors, etc.

Which industries rely on Precision Manufacturing?

The accuracy and reliability of Precision Manufacturing make it an indispensable supporting technology for many high-end industries. The following are its key application areas:

(1) Aerospace and Defense

Aircraft engine blades, satellite precision parts, etc. need to withstand extreme environments, and any slight error may lead to catastrophic consequences. Precision manufacturing technology ensures the performance stability of parts under high temperature and high pressure through strict quality control. For example, turbine blades are manufactured using directional solidification technology, and the error must be controlled within ±5 microns.

(2) Medical equipment and biotechnology

Medical devices such as surgical robots, artificial joints, and heart stents have extremely high requirements for biocompatibility and dimensional accuracy. Precision manufacturing can not only achieve personalized customization of complex structures (such as 3D printing titanium alloy bones), but also reduce the rejection of implants to the human body through micron-level polishing.

(3) Automobiles and new energy vehicles

From the gearbox gears of traditional fuel vehicles to the battery modules of electric vehicles, precision manufacturing technology directly affects product performance and safety. For example, the coating thickness of the battery pole of electric vehicles must be accurate to ±1μm to balance energy density and charge and discharge efficiency.

(4) Electronics and semiconductors

Chip manufacturing is one of the pinnacle areas of precision manufacturing. When the photolithography machine etches circuits on silicon wafers, the accuracy must reach the nanometer level (such as 5nm process). In addition, consumer electronic components such as mobile phone camera modules and flexible circuit boards (FPC) also rely on precision processing technology.

(5) Energy and environmental protection equipment

Wind turbine bearings, nuclear reactor cooling system components, etc. need to operate stably under long-term high loads. Precision manufacturing extends equipment life and reduces maintenance costs through surface strengthening treatment (such as ion implantation) and precision assembly.

Technical advantages and future trends of Precision Manufacturing

As market demand develops towards customization and miniaturization, precision manufacturing is accelerating its evolution in the following directions:

Intelligent upgrade: AI algorithms monitor processing parameters in real time and automatically correct deviations (such as adaptive control systems);

Green manufacturing: Reduce raw material consumption through precision molding (such as metal additive manufacturing to reduce scrap rate);

Cross-border integration: Combine with bioengineering and photonics to develop emerging products such as microfluidic chips and optical lenses.

From high-end equipment to daily consumer products, Precision Manufacturing is redefining the standard of “quality”. For enterprises, investing in precision manufacturing technology is not only the key to improving product competitiveness, but also a passport to integrate into the global high-end supply chain. In the future, with the breakthroughs in technologies such as quantum computing and ultra-precision machine tools, precision manufacturing will open a new chapter of the broader industrial revolution.