The Invisible Engine: Why Your Equipment Depends on a Single Shaft

Have you ever stopped to think about why some industrial machines run smoothly for many years while others deal with constant shaking and break down way too early? The real secret usually stays hidden deep inside the machine, specifically in the Rotor Shaft. As the main part that carries power and keeps everything balanced, this one single piece decides how long your whole system will last.

When a shaft fails, the trouble is never small. You have to deal with stopped work lines, very expensive quick repairs, and the chance of hurting other high-end parts that are connected to it. Choosing a carefully made shaft is not just a buying choice; it is like having a safety plan for your daily work. You want to make sure your machines stay running without any sudden surprises.

Meet Your Precision Partner: Foshan Ruizheng

If you are tired of “standard” parts that do not quite fit your special needs, you need a partner who treats every tiny measurement with great care. Since 2013, Foshan Ruizheng Machinery Manufacturing Co., Ltd. has grown from a small, dedicated lathe shop into a strong leader in making very exact parts. We do not just “make” things; we fix the mechanical troubles that keep engineers worried at night.

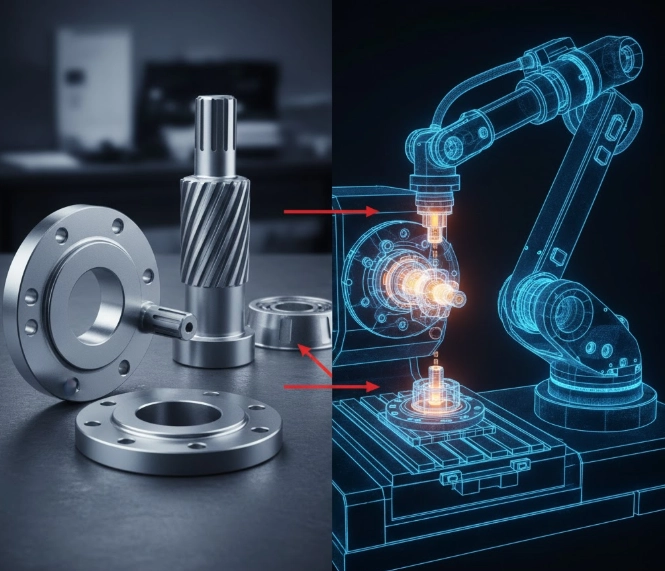

Whether you need custom shafts that are not the usual size or complex bearing seats, our factory—which uses smart robotic systems and special rooms where the temperature never changes—makes sure that what you get is exactly what you planned on paper. We are a National High-tech Enterprise that has spent a long time making the perfect shafts for big global leaders, and we are totally ready to do the same for you. We believe in building a real human connection with our clients, making sure you feel supported at every step of the process.

Why Precision is the Only Cure for Mechanical Failure

Mechanical trouble in industrial machines is almost never an accident; it is usually the result of too much stress building up over time. In fast-moving situations, even a tiny mistake in how centered a part is can lead to a “death wobble” that ruins bearings and seals. By picking parts made with high-level skill, you stop the causes of these breaks right at the start.

Achieving 0.001mm Accuracy: More Than Just a Number

In the world of machine tools and industrial equipment, “close enough” is a plan for trouble. When your rotor shafts are made to a tiny accuracy of 0.001mm, you are choosing a level of fit that ensures perfect movement inside your four-axis and five-axis machines. This extreme care reduces rubbing, lowers the heat that builds up, and makes sure your equipment works at its best even when the work is very heavy. It means your machines can run faster and longer without getting tired.

The Role of Material Integrity and Heat Treatment

Failure often starts with the metal getting weak. By picking the best materials like alloy steel or stainless steel and using professional heat treatment (which we measure in HRC), the outside hardness and the inside strength of the shaft are made just right. This careful work allows the shaft to handle the heavy twisting forces common in big industrial machines without cracking or bending. It is about making sure the metal is tough enough for the job you need it to do.

Tailored Solutions for the Modern Industrial Landscape

Your needs are very specific, so the parts you use should be just as specific. Parts you buy “off the shelf” often make you change your design in ways that lead to worse performance. Custom making is the bridge between a machine that just “works” and a machine that works perfectly.

Supporting the New Era of Robotics

The growth of industrial robotic arms and robots that look like humans has put new, big needs on shaft parts. these jobs need shafts that can change direction very quickly and stay in the exact right spot. High-level flanges and bearing seats work together with the rotor shaft to give the steady base needed for these important parts of industrial machines. We focus on making these parts move as smoothly as possible.

One-Stop Procurement for Maintenance and Repair

For people who fix machines or sell parts, finding every single piece can be a giant headache. We make this much easier by being a one-stop shop for everything. We do not just provide the shafts; we also help with the parts that wear out fast, like screws, seals, and bearings. This makes sure every single part of your machine meets the same high-quality rules. You won’t have to worry about a cheap screw ruining an expensive shaft.

Reliability Through Rigid Quality Management

You need to be sure that the part you put in your machine today will act exactly like the one you get six months from now. Being the same every time is the mark of a professional maker, supported by global certificates and very tough testing.

Triple-Layer Inspection Protocol

To make sure that no broken or bad part ever reaches your shop, a very strict “three-check” system is used:

- First-Piece Check: We check the very first part to make sure the machine is set up right and follows your 2D or 3D drawings perfectly.

- Full-Process Check: We watch the work while it is happening to make sure the quality stays the same and does not change.

- Final Shipping Check: This is a last look in our special temperature-controlled room to be 100% sure the measurements are right before the part is boxed up.

Compliance with Global Standards

Doing business in Europe, America, or Japan needs more than just good parts; it needs the right papers to prove the quality. Providing material reports, size check reports, and RoHS papers makes sure your equipment follows all the rules and quality marks. We make sure you have everything you need for a smooth and easy process.

Seamless Logistics and Global Service

Buying exact parts should be as smooth as the parts themselves. From the second you send us a drawing to the day the box arrives at your door, the whole path is made to be clear and fast.

Speed That Matches Your Production Cycle

In the world of industry, time is truly money. You can expect us to look at your drawings and give you a price within just 24 hours. Whether you need a small group of parts for testing or a very large order, we tell you the delivery times clearly: 20-30 days for normal parts and 40-60 days for very complex, high-end pieces. We work hard to stay on your schedule.

Global Delivery and After-Sales Support

Being far away should not stop you from getting great quality. We support many ways to pay and offer DDP (Delivered Duty Paid) shipping, so getting your parts is very easy. If you run into trouble putting the parts together, we can help you through a video call. We give you tips on how to use the parts and how to assemble them, making sure your project keeps moving forward without stopping.

Conclusion: Protect Your Assets with Precision

A rotor shaft is the backbone of your machine. By picking high-level, custom-made parts, you are stopping failures before they happen, cutting down on repair costs, and making your equipment last much longer. When you cannot compromise on quality, choose a partner that cares about exact measurements as much as you do.

Ready to make your machines more reliable? Send your drawings to Ruizheng today for a 24-hour check and let us help you build a future where your machines never fail.

FAQ

Q: Can you help me with technical advice on how to put the parts together?

A: Yes, we provide professional advice on assembly fit and how to use the parts to make sure they work perfectly in your specific machine. We want to make sure the installation is as easy as possible for you.

Q: What happens if I find a quality problem with a part I ordered?

A: We stand behind what we make. If there is a problem with the quality, we support returns and trades. We also give you a report that explains what went wrong so we can make sure it never happens again. Your satisfaction is our main goal.

Q: Do you help with small orders for testing or fixing things?

A: Definitely. We support working together on small trial orders or making samples. This lets you check the design and the quality before you decide to buy a very large amount. It is a great way to start our partnership.