Dimensional accuracy is key to making parts that work perfectly in CNC turning. It ensures every piece fits its design exactly. This article explores why accuracy matters, how the best CNC precision turning shaft helps, and how Ruizheng delivers top-notch results.

What Is Dimensional Accuracy?

Close Parts Match Their Plans

Dimensional accuracy means a machined part sticks closely to its planned sizes. It’s measured in tiny units like microns or millimeters. This shows if the part meets tight rules needed for it to work right. Even a small mistake, like 0.001 mm, can cause big problems. Parts might not fit or could break.

The Accuracy Is a Big Deal

Getting sizes right is super important in CNC machining. It affects how well parts work, how safe they are, and if they last. In fields like planes, cars, or medical tools, tiny errors can lead to serious issues. So, high accuracy isn’t just about quality. It’s also about following strict industry rules and keeping things reliable.

The Role of Best CNC Precision Turning Shaft in Achieving Accuracy

How Shafts Shape Machining Results

The CNC precision turning shaft is a big player in getting good results. A top-quality shaft keeps the workpiece steady as it spins. This cuts down on shakes or wobbles that mess up sizes. Bad shafts can cause errors like runout or poor alignment. These ruin the final part’s measurements.

Features That Boost Precision

The best CNC precision turning shaft has special traits to improve accuracy:

- It stays balanced during fast spins.

- It’s made from strong materials with heat treatment.

- It keeps sizes super tight to avoid mistakes.

- It works well with automated machines for steady results.

High precision and strong reliability make these shafts perfect for tough jobs with high speeds or heavy loads.

How Ruizheng Delivers High-Quality CNC Turning Shafts

Top Standards at Ruizheng

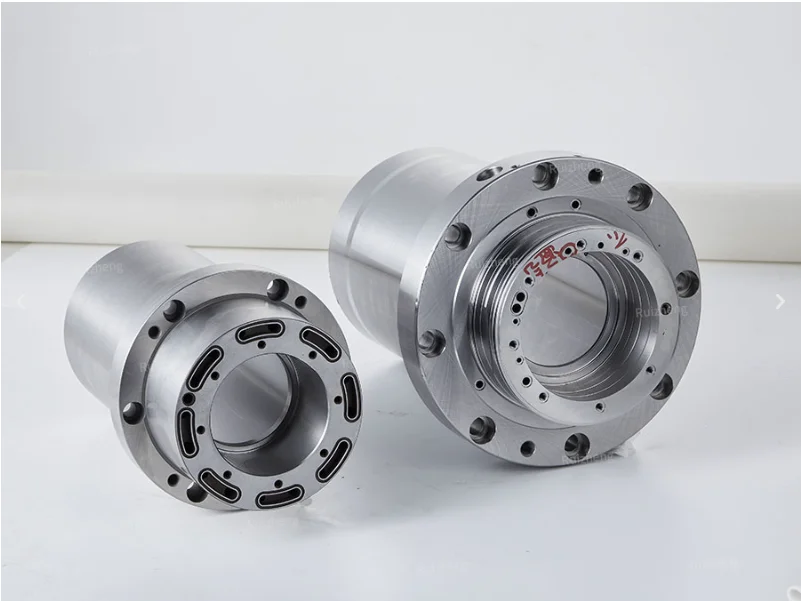

Ruizheng, started in 2013, is great at making high-precision CNC precision turning shafts and custom parts. They follow the ISO 9001 quality system strictly. Every part gets checked at the start, during, and before shipping. This ensures each shaft matches its exact sizes perfectly.

Modern Machines and Skilled Workers

Ruizheng has grown into a modern factory. They use lathes, milling machines, grinders, and a constant-temperature testing room. They also have robotic systems for loading and unloading. These tools help them hit accuracies as tight as 0.001 mm. Skilled workers watch every step to make sure results are top-notch.

Custom Options for Your Needs

Ruizheng makes parts based on your 2D or 3D drawings. Need stainless steel or titanium? They’ve got you covered. Want heat treatment for tougher parts? They can do that too. Ruizheng also helps with extras like screws, seals, or bearings to fit your project.

Factors That Influence Dimensional Accuracy in CNC Turning

Machine Strength and Stability

A strong machine stops bending under pressure. Shakes or flexing during work can mess up sizes. High-end CNC machines have solid frames. They also have systems to reduce vibrations. This keeps parts accurate.

Condition of Cutting Tools

Worn or poorly shaped tools hurt accuracy. Dull tools rub instead of cut cleanly. This can heat up parts or change their shape. Keeping tools sharp and well-designed ensures clean cuts and good sizes.

How Materials Behave

Different materials act differently when machined. Plastics might swell with heat. Metals might get hard where cut. Knowing how materials work helps keep sizes tight and accurate.

Temperature Changes During Work

Cutting creates heat. This can make tools or parts expand a bit. Without cooling or a steady-temperature room, sizes can go off. Ruizheng’s constant-temperature testing room helps keep measurements spot-on.

Benefits of Using Best CNC Precision Turning Shaft for Accurate Results

Perfect Fit with Other Parts

Accurate shafts make parts like gears or bearings fit smoothly. This makes assembly easier. It also improves how machines work overall.

Fewer Bad Parts

Top-quality shafts keep sizes consistent across many parts. This means fewer mistakes in production. It saves time and materials. It also makes the process more efficient.

Better Performance Over Time

Well-made shafts with smooth finishes last longer. They resist wear even under tough conditions. This means products work well for a long time, even with heavy use.

Comparing Standard Shafts With Best CNC Precision Turning Shaft by Ruizheng

Strength and Wear Differences

Ruizheng uses strong materials like alloy steel, stainless steel, or titanium alloy. These have better hardness than standard options. Heat treatment makes them even tougher for heavy jobs.

Better Size Control

Standard shafts often have looser size rules. These don’t work for high-performance jobs. Ruizheng’s CNC precision turning shaft hits accuracies of 0.001 mm. This is perfect for projects needing exact fits.

Long-Lasting Reliability

Ruizheng’s shafts are built to last. They handle fast spins or changing temperatures well. Standard shafts might wear out or fail quickly in these conditions.

Real-World Applications Where Dimensional Accuracy Is Critical

Aerospace Parts

Planes need super precise parts for safety. CNC precision turning shafts must meet strict size rules to work under high stress or at high altitudes.

Car Engine Parts

In car engines, timing parts need perfect alignment. Even small size errors can hurt fuel use or cause breakdowns over time.

Medical Tools

Medical devices need tiny, exact sizes to work safely inside people. High-precision shafts ensure these tools work without issues.

Maintenance Tips for Keeping Your CNC Turning Shaft Accurate Over Time

Clean After Every Use

Dirt or bits left on shafts can mess up alignment. Cleaning after each job keeps future work accurate. It also protects the shaft’s quality.

Check for Wear Regularly

Look at shafts often with tools like micrometers. Spotting wear early stops it from hurting accuracy. This keeps parts working well.

Lubricate Moving Parts

Oil or grease cuts friction and heat. This stops parts from expanding due to heat. It also makes shafts last longer and stay accurate.

Choosing the Right Shaft for Your CNC Machine Setup

Match Shaft to Job Type

Different jobs need different shafts. Heavy tasks need tough materials. Tiny electronics need super precise sizes. Pick a shaft that fits your work’s needs. Material selection can improve machining outcomes by 30% when matched to application needs (Source: Thomasnet, thomasnet.com).

Check Machine Fit Before Buying

Make sure the shaft matches your machine’s setup. Check length, width, mounting style, and speed limits. This ensures the best CNC precision turning shaft works perfectly for your project.

FAQ

Q1: Why is dimensional accuracy important in CNC turning?

A: It ensures parts fit and work right. Even tiny errors can cause failures. Accuracy keeps machines safe and reliable.

Q2: How does Ruizheng ensure precision in CNC precision turning shafts?

A: They use advanced machines and strict checks. Every shaft is tested multiple times. This hits accuracies as tight as 0.001 mm.

Q3: Can Ruizheng customize shafts for my project?

A: Yes, they make parts from your drawings. You can pick materials or treatments. They also help with extras like screws or bearings.