In the fast-paced world of modern manufacturing, a sudden mechanical silence is a nightmare. When a heavy-duty machine stops turning, the heartbeat of your entire workshop skips a beat. You aren’t just losing a few minutes of work; you are losing your good name, missing your delivery dates, and watching your hard-earned money vanish. For the hardworking folks in maintenance, the fight against friction and rust never ends. Yet, the secret weapon to winning this long war is often a small part that many people ignore until it breaks: the bearing housing.

Most equipment failures do not happen because of a giant explosion. Instead, they are “slow deaths.” These happen when standard, basic parts struggle to survive in tough, specialized settings. If you are tired of the endless loop of “fix it, start it, and watch it break again,” it is time to look at the very base of your spinning gear. You need parts that don’t just “kind of fit” but are built to keep your business moving forward.

The Hidden Drain on Your Bank Account: Why Basic Parts Cost More

Have you ever stopped to calculate the real price of a “cheap” or standard bearing housing? The price tag you see on the invoice is only a tiny part of the true story. When a basic housing fails to keep a tight seal or starts to rust too early, the extra costs hit you like a wave. You end up paying for emergency repair crews, buying new bearings to replace the ruined ones, and facing the terrible cost of a machine tool that is sitting completely still.

Why Off-the-Shelf Parts Fail in Your Shop

Basic housings are usually made for “average” conditions. But your floor isn’t average. You are dealing with incredibly fast spindles, constant coolant spray, and the heavy shaking of serious industrial equipment.

- Weak Seals: Generic sizes often leave tiny gaps that you can’t see.

- Thin Materials: Regular cast iron often lacks the toughness needed for busy machine tool accessories.

- Heat Problems: Poor heat flow in cheap metals basically “cooks” your oil, which leads to a seized bearing.

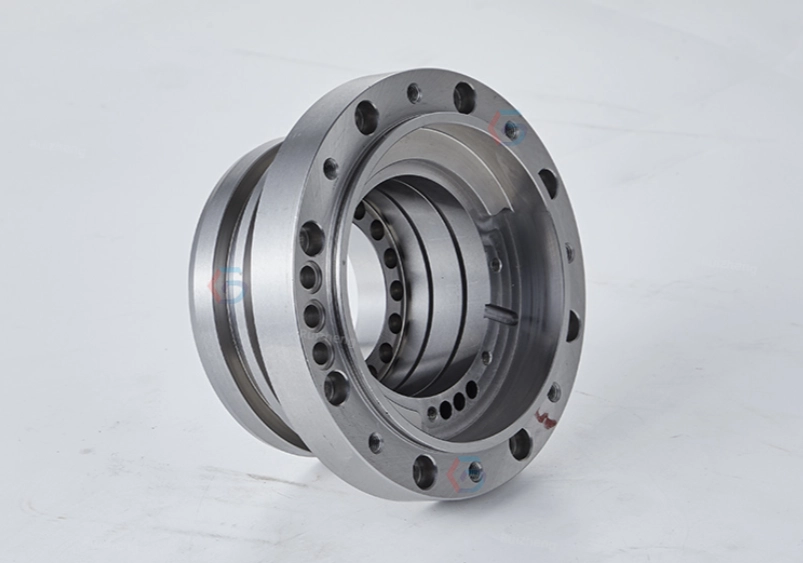

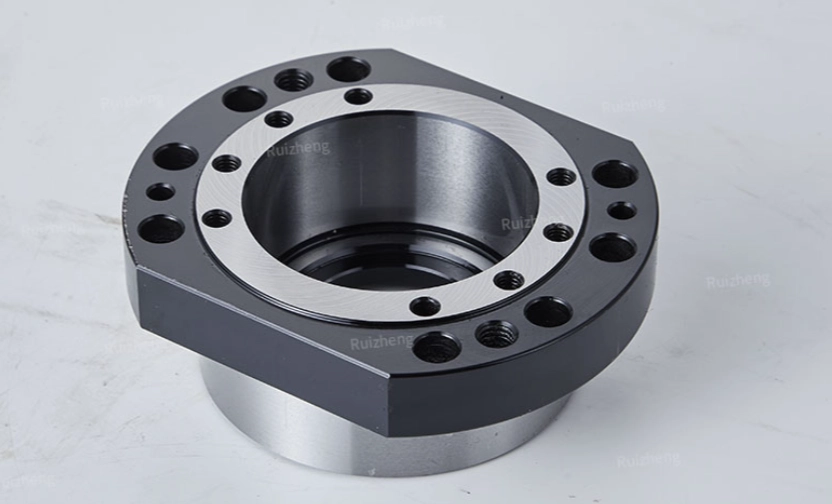

Finding a partner who cares about tiny details instead of just making thousands of the same part is the first step toward sleeping better at night. For those who want a mix of real skill and smart engineering, Ruizheng is a top-tier expert in CNC machining. This isn’t just a shop with some tools; it is a specialized center where experienced builders treat every tiny measurement as a huge deal. By mixing high-tech machines with a human touch to solve real problems, they make sure your parts show up with the exact specs needed to win in tough jobs.

Built to Last: Picking the Best Shield for Your Gear

If you want to make your industrial equipment live a lot longer, you have to start with the “skin” of the machine. The material used for your housing is the first line of defense against a rough world. While a lot of companies stick to basic, weak metals, the smartest maintenance plans involve picking materials that don’t care about rust or wear.

The Real Strength of Super Duplex Steel

In places where water, steam, or strong chemicals are used every day, normal materials just fall apart. This is where high-end metals like Super Duplex Steel change everything. When you pick this material for your housings, you get:

- Amazing Rust Protection: It lasts way longer than basic stainless steel when it gets hit by strong cleaning chemicals.

- Great Physical Strength: It keeps its shape even under huge pressure, making sure the bearing inside stays perfectly straight.

- Years of Extra Life: You can easily double or even triple the time between your housing checkups.

Moving from a part that fails to a part that stays fixed requires more than just better metal. It requires a building process that truly understands how the metal works. When your housing is built to last, your machine tool stays running, and your repair schedule finally becomes something you can actually predict.

Precision CNC Machining: Your Guard Against Leaks

Even the most expensive metal is totally useless if the shape is wrong by even a tiny bit. Oil leaks are the quiet killers of industrial equipment. Once the oil gets out, friction goes up, heat starts to climb, and the bearing begins its fast trip to the trash can.

Stopping the “Quiet Leak” for Good

How do you make sure you have an environment with zero leaks? The answer is in the perfect fit of the parts. By using very advanced cutting and shaping methods, we can hit measurements that basic casting simply cannot reach.

- The Perfect Fit: A custom bearing housing processing service makes sure the gap between the housing and the bearing is tight enough to stop shaking, but just loose enough to allow the metal to grow when it gets hot.

- Smooth Surfaces: Extremely smooth internal surfaces made by CNC machines mean your seals sit perfectly flat. This keeps the bad dirt out and the good oil in.

- Better Cooling: Custom shapes can include better outer designs that work like a fan, pulling heat away from the spinning shaft.

By looking at these tiny, microscopic details, you aren’t just buying a metal box. You are putting your money into a smart barrier that keeps your machine tool accessories running much cooler and for a much longer time.

More Than Just Specs: What This Does for Your Business

By now, you might be thinking about the technical numbers, but let’s talk about what really matters: your results. Buying high-quality, custom-made parts isn’t just spending money—it is a smart way to reach “Cost Reduction and Efficiency Enhancement”.

Slashing Your Machine Downtime

When your bearing housings are built exactly for your specific industrial equipment, you stop panicking about breaks and start controlling your success.

- Fewer Part Swaps: Spend your weekends with your family, not at the factory trying to fix a stuck spindle.

- Better Quality Work: A steady bearing housing means your machine tools won’t “chatter” or shake. This leads to much better parts for your own customers.

- Saving Resources: You will use a lot less oil and buy fewer replacement parts throughout the whole year.

Why Going Custom is the Only Smart Choice

Every single machine has its own way of working—its own shake, its own heat, and its own speed. The idea that “one size fits all” is a lie that leads straight to the scrap pile. Going custom lets you change the housing design to fix the specific weak spots of your current setup. Whether it is a unique machine tool accessory or a vital industrial equipment part, the goal remains the same: total, 100% reliability.

Take Charge of Your Factory’s Future

The road to a better, more profitable factory starts with just one choice. You can keep buying cheap parts every few months and hope for the best, or you can install a solution that is built to outlive the machine itself.

You deserve parts that work just as hard as you do. When you choose precision-made housings, you are protecting your bearings, your spindles, and your company’s bank account. High-level manufacturing needs high-level support to stay on top.

Are you ready to get rid of the weak spots in your machines? The engineering team is standing by to look at your unique problems and give you the exact parts you need to stay ahead of everyone else in your field.

Reach out to us today to talk about your custom project and get a professional look at what you need.

FAQ

Q: How does a custom bearing housing save me money if the first price is higher?

A: Even if the first price is higher than a factory-made part, you save money in three big ways: you go much longer between repairs, you stop expensive bearing damage before it happens, and you don’t lose money from your machines sitting idle. Over a couple of years, a high-quality housing usually costs about 40% less than buying many cheap, failing ones.

Q: Can these custom housings be made to fit my old machines without changing the whole machine?

A: Absolutely. The best part about CNC machining is that we can copy or improve on your exact old measurements. We can make the outside fit your old bolts perfectly while making the inside much stronger and better at sealing than it ever was before.

Q: Why should I care about Super Duplex Steel for my industrial equipment?

A: Super Duplex Steel is almost twice as strong as regular stainless steel. It is also much better at stopping tiny holes and cracks from forming when it gets wet or dirty. In machines where you use a lot of coolant or fluids, this keeps the housing from wearing down and losing its perfect shape over time.