In the realm of advanced manufacturing, precision parts machining is the cornerstone of producing components with exacting accuracy and reliability. From microscopic medical implants to aerospace engine parts, this process ensures that every detail meets stringent specifications. But what exactly is precision parts machining, and why is it indispensable across so many industries? This article explores its definition, applications, and the transformative advantages it delivers.

What Is Precision Parts Machining?

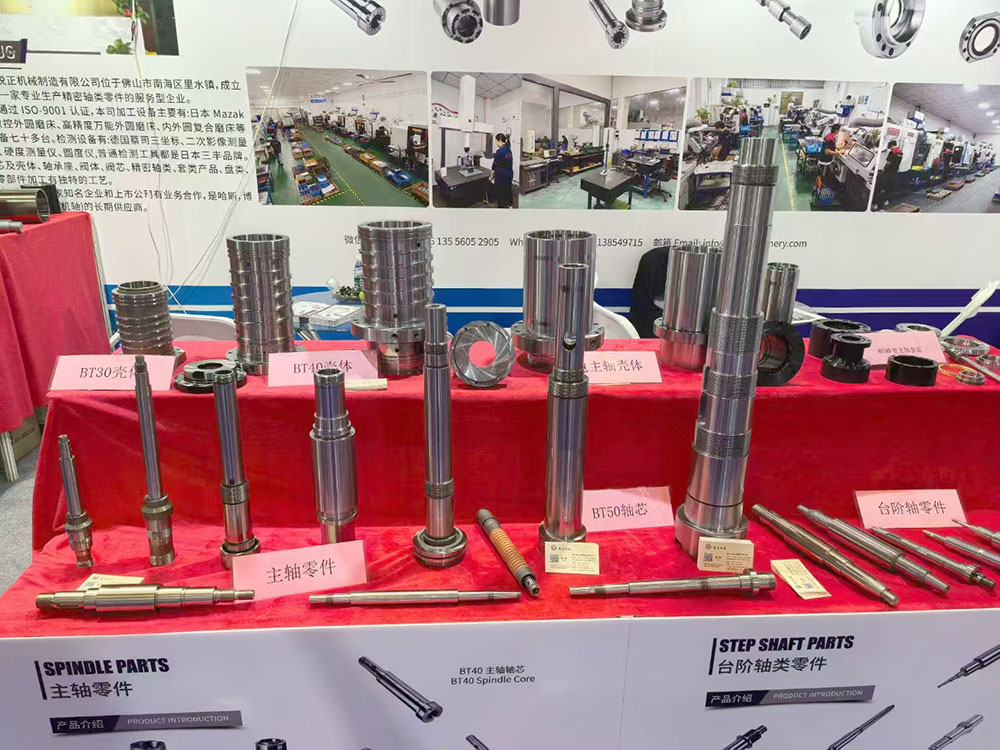

Precision parts machining is a subtractive manufacturing process that uses computer-controlled tools, such as CNC (Computer Numerical Control) machines, to shape raw materials into highly accurate components. Unlike conventional machining, which focuses on bulk production, this method prioritizes micron-level tolerances (often as tight as ±0.005 mm or less) and flawless surface finishes.

Key features of precision parts machining include:

Advanced Technology: CNC mills, lathes, and multi-axis systems automate complex cuts with minimal human intervention.

Material Versatility: Metals (aluminum, titanium, stainless steel), plastics, ceramics, and composites can all be machined.

High Repeatability: Computer programming ensures identical results across large production runs.

Customization: Tailored designs accommodate unique geometries, threads, or intricate features.

This process is ideal for applications where even minor deviations could compromise performance, safety, or durability.

Industries That Rely on Precision Parts Machining

Nearly every sector requiring high-performance components utilizes precision parts machining. Below are the most prominent industries:

1. Aerospace and Defense

Aircraft engines, landing gear, and satellite systems demand components that withstand extreme temperatures, pressures, and vibrations. Precision parts machining produces lightweight yet durable parts like turbine blades and fuel nozzles, ensuring compliance with strict aviation standards.

2. Medical and Biotechnology

Surgical tools, joint replacements, and diagnostic equipment require biocompatible materials and sterile finishes. Machined parts must meet FDA regulations, making precision parts machining vital for implants, MRI machine components, and disposable surgical devices.

3. Automotive and Electric Vehicles (EVs)

From engine pistons to EV battery connectors, automakers rely on precision-machined parts for efficiency and reliability. The shift toward lightweight electric vehicles further drives demand for components that reduce weight without sacrificing strength.

4. Electronics and Semiconductor Manufacturing

Microchips, heat sinks, and sensor housings require microscopic precision. Precision parts machining enables the production of miniaturized, heat-resistant parts essential for smartphones, computers, and IoT devices.

5. Energy and Renewable Technology

Wind turbines, solar panel mounts, and nuclear reactor components depend on machined parts to maximize energy output and durability. Precision ensures these systems operate efficiently in harsh environments like offshore wind farms or desert solar arrays.

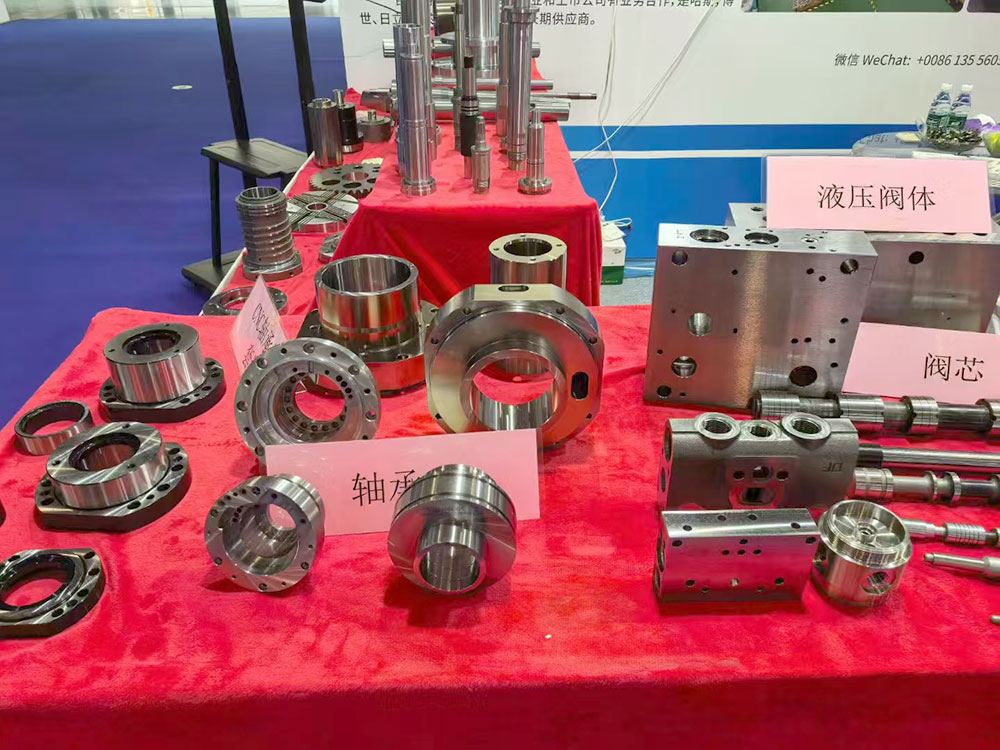

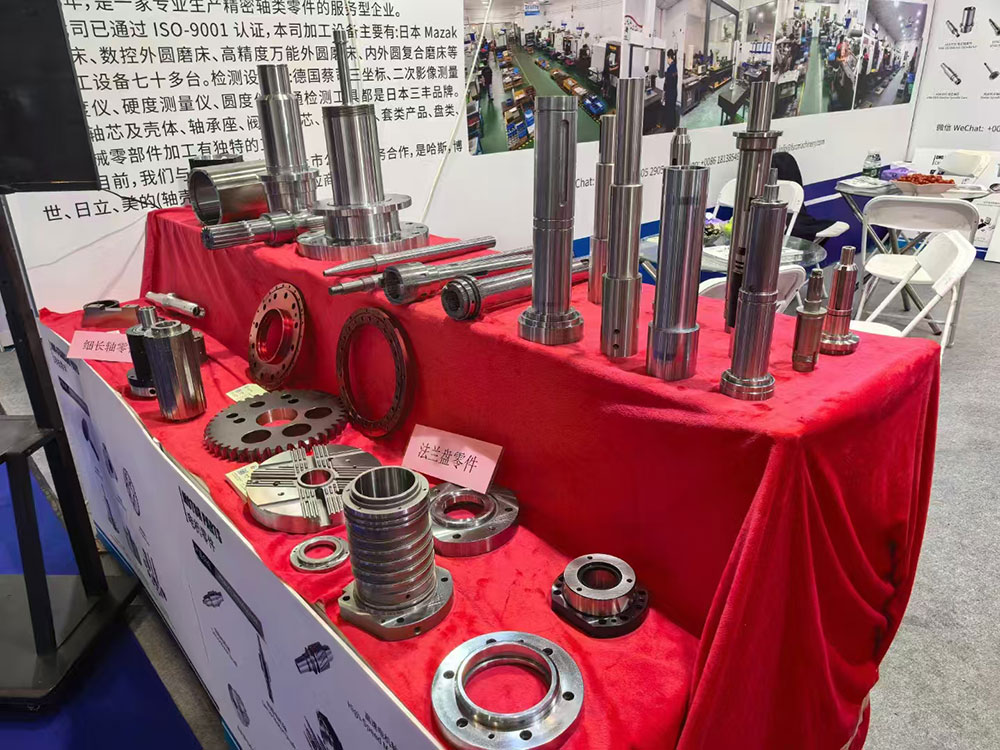

6. Industrial Machinery and Robotics

Gears, hydraulic systems, and robotic arms require parts that maintain tight tolerances under constant stress. Precision parts machining minimizes friction and wear, extending equipment lifespan in factories and warehouses.

Advantages of Precision Parts Machining

Investing in precision parts machining offers businesses a competitive edge through:

1. Unmatched Accuracy and Consistency

CNC technology eliminates human error, delivering components that fit perfectly into complex assemblies. This precision reduces defects, rework, and costly delays.

2. Enhanced Material Efficiency

Advanced software optimizes cutting paths, minimizing material waste. For expensive alloys like titanium or Inconel, this translates to significant cost savings.

3. Support for Complex Designs

Multi-axis CNC machines can create intricate shapes, internal channels, or micro-sized features that traditional methods cannot achieve. This flexibility fosters innovation in product development.

4. Scalability for High-Volume Production

Once a design is programmed, precision parts machining can replicate thousands of identical parts quickly, making it ideal for both prototypes and mass production.

5. Improved Product Performance and Lifespan

Precision-machined components reduce friction, heat buildup, and mechanical stress, enhancing the durability and efficiency of end products.

6. Compliance with Industry Standards

Industries like aerospace and healthcare require components to meet rigorous certifications (e.g., ISO, AS9100). Precision parts machining ensures adherence to these benchmarks.

Precision parts machining is more than a manufacturing process—it’s a catalyst for innovation across industries. By delivering accuracy, scalability, and material versatility, it empowers businesses to create cutting-edge products that meet today’s demanding standards. As technology evolves, the role of precision parts machining will only grow, driving advancements in fields like robotics, clean energy, and smart electronics.

For companies aiming to stay ahead, partnering with a skilled precision parts machining provider isn’t just an option; it’s a strategic necessity.