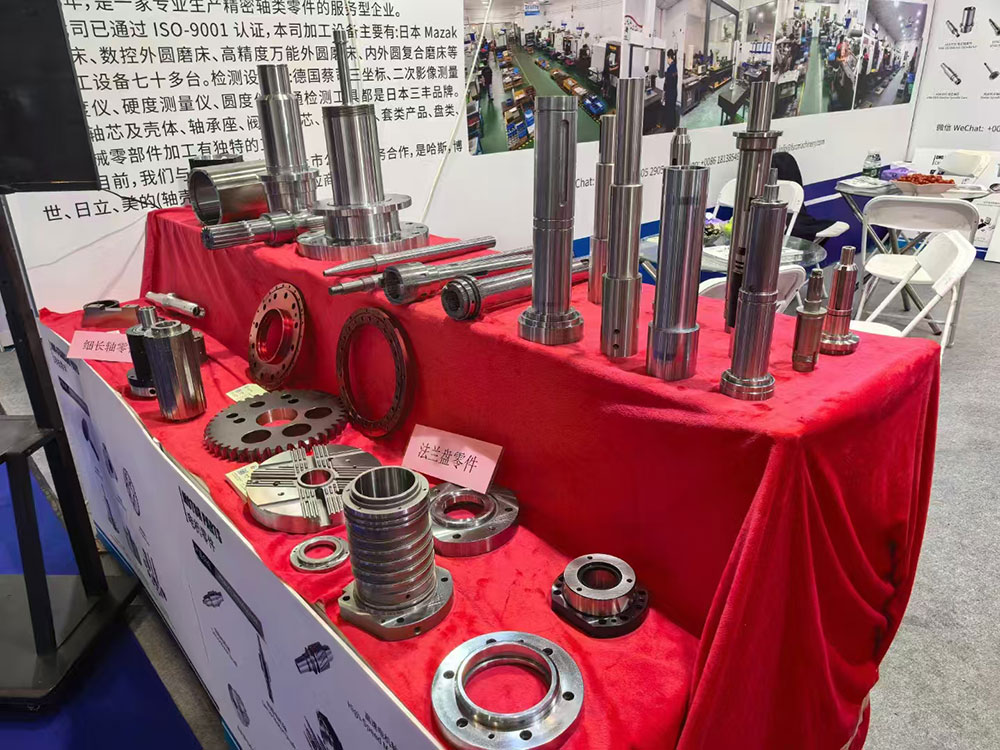

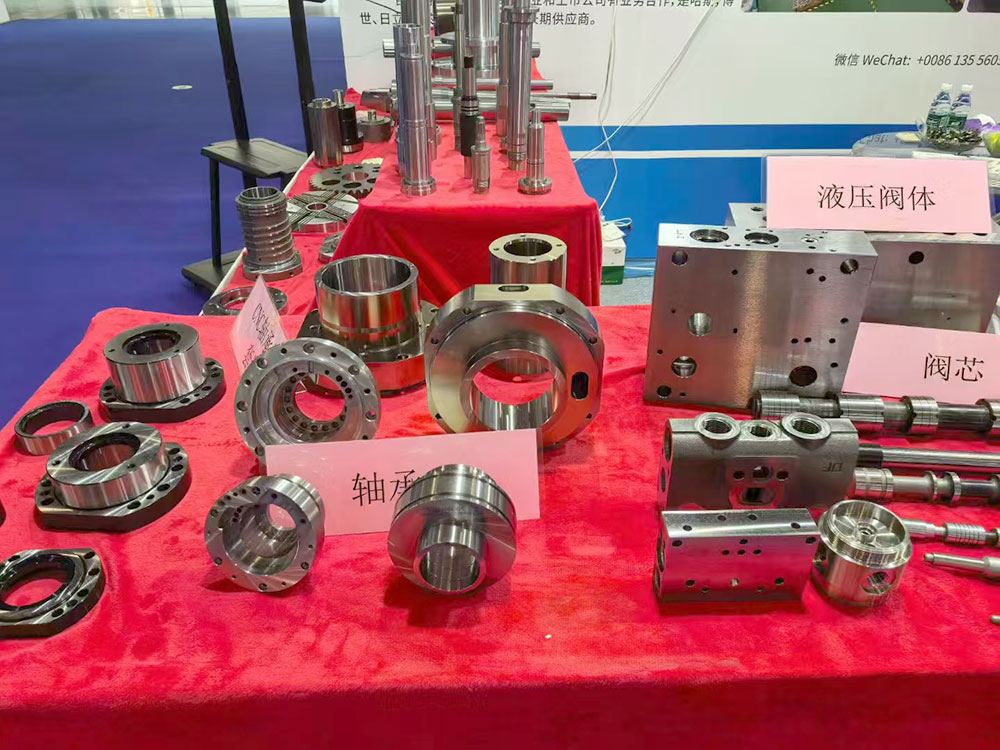

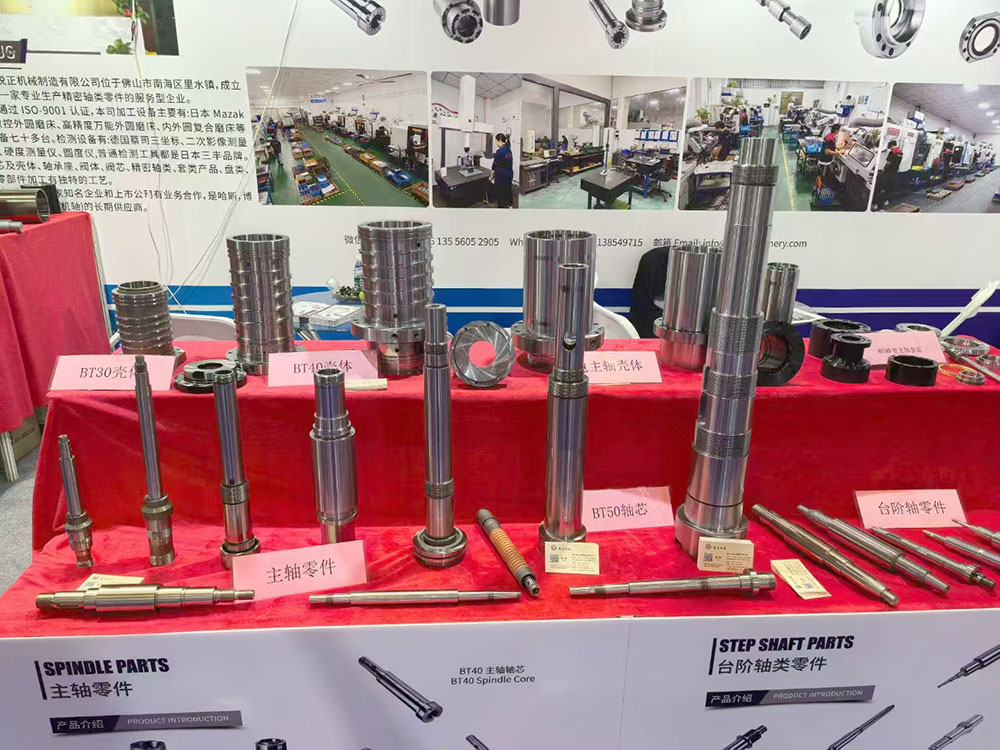

Custom precision machined parts play a vital role in modern manufacturing, ensuring high precision, durability, and performance across a wide range of industries. These parts are crafted using advanced machining techniques to meet precise specifications, making them indispensable components in applications where precision is paramount.

This article will explore the benefits of custom precision machined parts and highlight the key industries that rely on them for optimal functionality.

1. Benefits of Custom Precision Machined Parts

High Precision

Custom precision machined parts are manufactured using CNC (computer numerical control) machining, ensuring tight tolerances and repeatability. This level of precision is critical in industries where even minor deviations can cause equipment failure.

High-Quality Materials and Durability

These parts are often made from rugged materials such as stainless steel, aluminum, titanium, and engineered plastics to ensure long-term performance even in harsh environments.

Customization to Meet Specific Needs

Unlike off-the-shelf components, custom precision machined parts are designed to meet precise needs, whether it is complex geometry, unique dimensions, or special features.

Improve Efficiency, Reduce Waste

Precision machining minimizes material waste and increases production efficiency, making it a cost-effective solution for high-volume, specialized production.

2. Key Industries Relying on Custom Precision Machined Parts

Aerospace

The aerospace industry requires custom precision machined parts to manufacture critical components such as turbine blades, landing gear, and avionics housings. These parts must withstand extreme conditions while maintaining stringent safety standards.

Medical & Surgical Devices

Medical devices, implants, and surgical instruments require ultra-precision machining to ensure biocompatibility and perfect operation. Custom precision machined parts are essential for prosthetics, orthotics, and diagnostic equipment.

Automotive & Motorsports

From engine components to drivetrains, the automotive industry relies on custom precision machined parts to ensure performance, fuel efficiency, and reliability. High-performance motorsports applications also rely on the speed and durability of these parts.

Oil & Gas Industry

In harsh drilling and extraction environments, custom precision machined parts such as valves, pumps, and connectors must resist corrosion and high pressure while maintaining a tight seal.

Electronics & Semiconductor Manufacturing

Miniaturization and high-precision components are essential for circuit boards, microchips, and connectors. Custom precision machined parts ensure perfect functionality of sensitive electronic devices.

Industrial Machinery and Robotics

Automation and heavy machinery rely on precisely engineered components to run smoothly. Custom precision machined parts improve the performance and life of robotic arms, CNC machine tools, and assembly line equipment.

Custom precision machined parts are the backbone of modern manufacturing, offering unparalleled precision, durability, and customization. Industries ranging from aerospace to medical devices rely on these parts to maintain high performance and safety standards.

If your business requires high-quality custom precision machined parts, working with an experienced manufacturer ensures you get custom parts that meet your exact specifications.

By understanding the benefits and applications, you can make informed decisions that improve your production processes and product reliability.