Introduction to CNC Custom Processing Services

CNC (Computer Numerical Control) custom processing services play a pivotal role in modern manufacturing, allowing for the creation of intricate shapes and components with unparalleled precision. These services leverage advanced computer software to control machine tools, thereby transforming raw materials into high-quality finished products. The advent of CNC technology has revolutionized how industries produce complex geometries, making it possible to achieve precise dimensions and tight tolerances that are essential in various applications.

The significance of precision in manufacturing cannot be overstated. In industries where safety and efficacy are paramount, such as automotive, medical, and aerospace, adherence to stringent tolerances ensures that components perform as intended. For instance, in the medical field, custom-machined parts must meet exact specifications to avoid malfunctions that could jeopardize patient safety. Similarly, in the automotive sector, finely-tuned components are crucial for optimal vehicle performance and reliability.

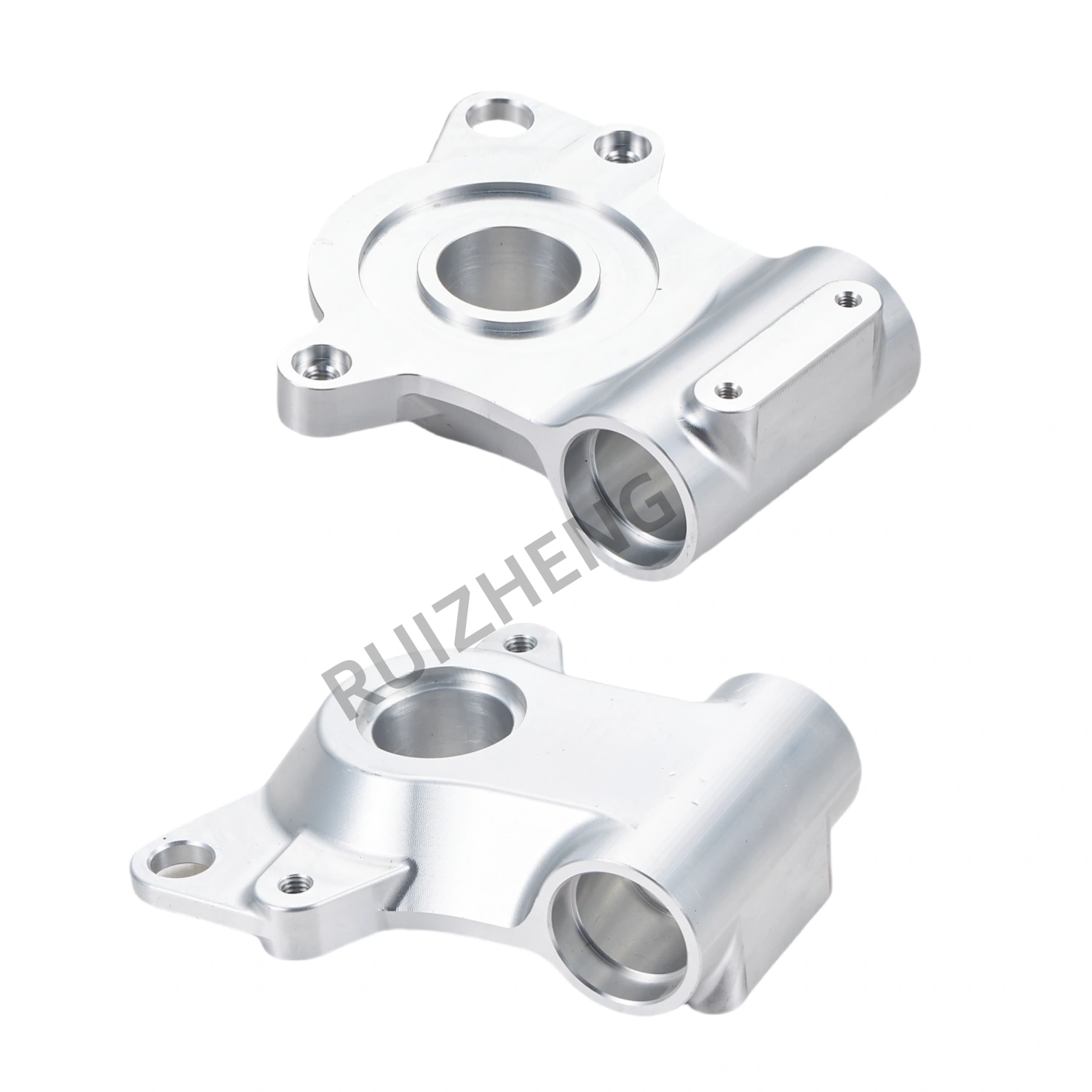

CNC custom processing services cater to a variety of materials, including aluminum, stainless steel, and brass. Each type of material presents unique challenges and requires specific machining strategies to achieve the desired end product. Aluminum, known for its lightweight and corrosion-resistant properties, is often favored in automotive applications. In contrast, stainless steel is prized for its strength and reliability in high-stress environments, making it a common choice for aerospace components. Brass, with its excellent machinability and acoustic properties, is frequently used in electrical fixtures and musical instruments.

This overview highlights the transformative impact of CNC technology on manufacturing. By enabling precise control over the machining process, CNC custom processing services have become essential for a broad array of industries, meeting diverse manufacturing demands while ensuring compliance with rigorous standards. The following sections will delve deeper into the specific applications and benefits these services provide across various sectors.

Applications and Advantages of High-Precision CNC Processing

High-precision CNC custom processing has become an essential element in numerous industries, offering tailored solutions to meet the intricate demands of modern manufacturing. One of the primary fields benefiting from CNC technology is the automotive industry, where precision is crucial for the production of components such as engine parts, gears, and custom fittings. The adoption of CNC machining enables manufacturers to create these parts with exact specifications, ensuring optimal performance and safety in vehicles.

The medical device sector also relies heavily on high-precision CNC processing. Devices such as surgical instruments, implants, and diagnostic equipment require meticulous craftsmanship. CNC technology allows for the manufacture of components that meet stringent regulatory standards while maintaining the precision needed for proper function. For instance, dental implants and orthopedic devices produced through CNC methods exemplify how advanced machining can enhance both the effectiveness and reliability of medical applications.

Aerospace technology demands the highest level of precision, given the critical nature of aircraft performance and safety. CNC processing is utilized for fabricating lightweight yet strong components like turbine blades, brackets, and fuselage sections. The ability to produce complex geometries through CNC machining means aerospace manufacturers can innovate and improve designs that traditional manufacturing methods might fail to achieve, thus pushing the boundaries of what is possible in aircraft engineering.

Beyond its applications, the advantages of high-precision CNC processing are notable. This technology enhances production efficiency, as automated systems can achieve consistently high levels of accuracy and repeatability, reducing waste and downtime. Furthermore, the versatility of CNC machines allows for the rapid changeover and adaptation to different production runs, catering to both high-volume and custom orders. By embracing high-precision CNC custom processing, companies across various industries can meet rigorous standards and fulfill customer requirements effectively.

Reviews

There are no reviews yet.