Understanding Customized Flanges and Their Materials

High-precision customized flanges play a vital role across a multitude of industries, functioning as crucial components in ensuring secure connections between various piping systems and mechanical assemblies. The choice of material for these flanges is pivotal, as it directly influences their performance characteristics such as strength, durability, and resistance to environmental factors. Commonly used materials in the production of customized flanges include carbon steel, stainless steel, and aluminum alloys, each with its unique advantages.

Carbon steel is renowned for its high tensile strength and ability to withstand significant pressure, making it an optimal choice for industrial applications that require robust and reliable connections. Its cost-effectiveness further enhances its popularity, especially in applications where budget constraints are a consideration. However, carbon steel flanges are generally susceptible to corrosion without proper protective coatings.

In contrast, stainless steel offers superior corrosion resistance, making it ideal for applications in environments that involve exposure to moisture or chemicals. Its inherent longevity and aesthetic appeal suit a variety of applications, from chemical processing to maritime operations, where hygiene and corrosion control are paramount.

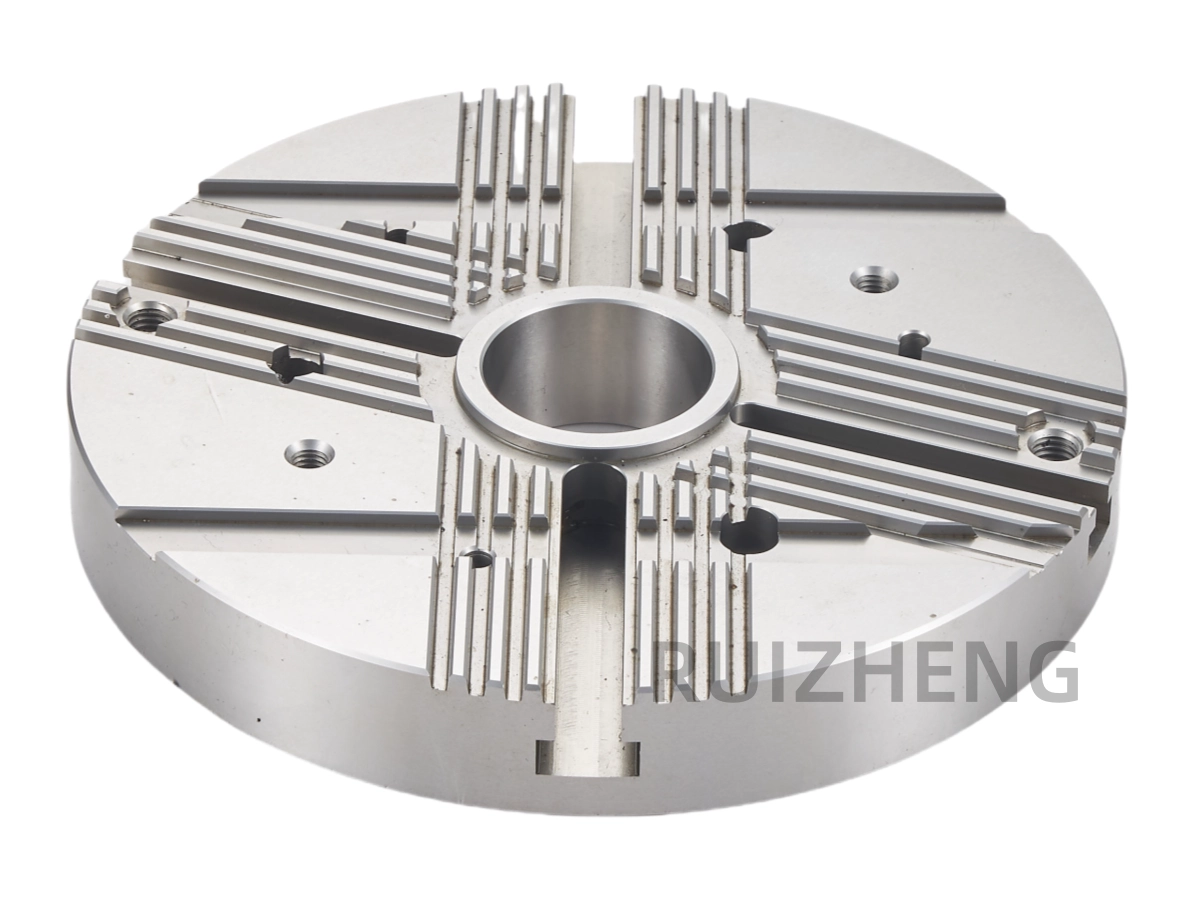

Aluminum alloy flanges, while lighter than their carbon or stainless steel counterparts, provide commendable strength-to-weight ratios. This property renders them particularly beneficial in applications where weight reduction is essential, such as in aerospace or automotive industries. Their manufactured designs often highlight complex shapes, including bearing seats, end covers, and housings, further enhancing their adaptability across multiple functions, including pipelines, mechanical equipment, and automation systems.

In summary, understanding the implications of material selection is crucial when utilizing high-precision customized flanges. The appropriate material ensures tight connections and facilitates successful applications in various industrial domains, ultimately contributing to the overall performance and reliability of machinery and systems. Careful consideration of material properties enables engineers and designers to optimize flange design, catering to the specific challenges of their projects.

Applications of High-Precision Flanges in Industry

High-precision customized flanges are essential components utilized across various industries, notably in energy, manufacturing, and chemical processing sectors. Their primary function is to provide secure connections in pipelines, ensuring the integrity and safety of fluid transport systems. For example, in the oil and gas industry, high-precision flanges are crucial for connecting pipes, valves, and equipment, allowing for seamless operation under high pressure and temperature conditions. The precise engineering of these flanges minimizes the risk of leaks, thereby enhancing operational safety and environmental protection.

In manufacturing, high-precision customized flanges support a wide range of mechanical equipment, including pumps, turbines, and reactors. The accuracy of these flanges leads to improved alignment and stability, which is vital for optimal equipment performance. A case in point is the use of custom flanges in automotive manufacturing, where precise connections can significantly affect the efficiency and durability of the assembled units. The reliability that comes from using high-quality flanges ensures minimal downtime and maintenance, maximizing production output.

Another critical application is in automation systems, where high-precision flanges assist in the integration of various components. They facilitate the connection between sensors, actuators, and controllers, promoting smoother operations and enhanced functionality. In industries such as food and beverage, where hygiene standards are paramount, high-precision flanges made from stainless steel or other suitable materials are indispensable. They ensure that there are no contaminations in the piping systems, adhering to regulatory standards and ensuring product safety.

When selecting the appropriate type of high-precision flange for specific needs, factors such as material compatibility, pressure rating, and temperature tolerance must be considered. Understanding the unique requirements of each application will lead to better performance and enhanced life cycle of the components in use.

Reviews

There are no reviews yet.