Precision manufacturing is a cornerstone of modern engineering, ensuring that components meet exact specifications for performance and reliability. Among the most critical processes in this field is shaft machining, which involves the production of high-precision rotating shafts used in industries such as automotive, aerospace, and industrial machinery. This article explores the key techniques, challenges, and advancements in shaft machining within the realm of precision manufacturing.

The Importance of Precision in Shaft Machining

Shafts are fundamental components in mechanical systems, transmitting torque and supporting rotating elements. Any deviation in dimensions or surface finish can lead to premature wear, vibration, or even catastrophic failure. Precision manufacturing ensures that shafts are machined to tight tolerances—often within micrometers—guaranteeing optimal performance.

Key aspects of shaft machining include:

Material Selection: High-strength alloys, stainless steel, and titanium are commonly used for durability and corrosion resistance.

Dimensional Accuracy: CNC (Computer Numerical Control) machines ensure precise diameters, lengths, and geometric tolerances.

Surface Finish: Advanced grinding and polishing techniques minimize friction and wear.

Advanced Techniques in Shaft Machining

Modern precision manufacturing leverages cutting-edge technologies to enhance shaft machining efficiency and accuracy:

CNC Turning & Milling: Automated lathes and milling machines produce complex geometries with minimal human intervention.

Grinding & Honing: Ultra-precise grinding wheels achieve mirror-like finishes for high-performance applications.

Laser Measurement: In-process inspection systems verify dimensions in real time, reducing defects.

Additive Manufacturing: Hybrid techniques combine machining with 3D printing for customized or lightweight shafts.

Challenges & Solutions

Despite technological advancements, shaft machining faces challenges such as thermal deformation, tool wear, and vibration. Precision manufacturing addresses these issues through:

Coolant Optimization: Minimizes heat buildup during machining.

Tool Material Innovations: Diamond-coated and carbide tools extend tool life.

Dynamic Balancing: Ensures smooth operation of rotating shafts.

Shaft machining is a vital discipline within precision manufacturing, demanding expertise, advanced machinery, and rigorous quality control. As industries push for higher efficiency and durability, continuous innovation in machining techniques will remain essential. By embracing automation, real-time monitoring, and new materials, manufacturers can achieve unparalleled precision in shaft production—driving progress across engineering applications.

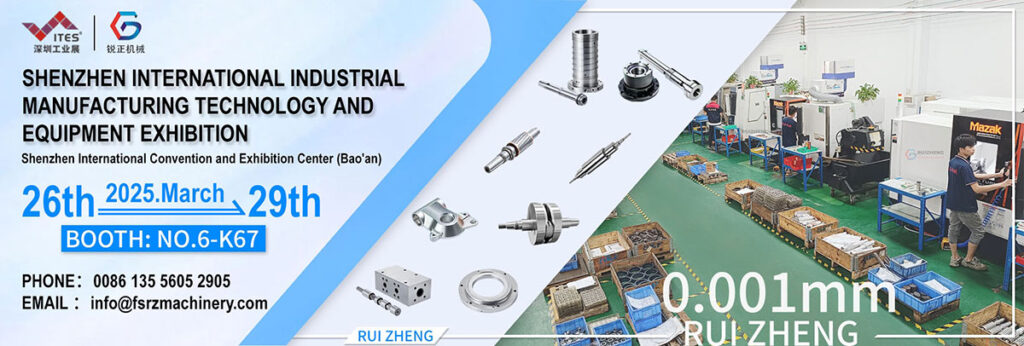

This article “Precision Manufacturing: The Art and Science of Shaft Machining” is originally shared by Foshan Ruizheng Machinery (spindleshaft.com). You can follow our factory diary to learn more about our factory information.