In today’s fast-paced industrial landscape, Precision Machining Manufacturing stands as a cornerstone of modern production. This advanced manufacturing method combines cutting-edge technology with meticulous engineering to create components with unparalleled accuracy and consistency. From aerospace to medical devices, industries rely on precision machining to meet stringent quality standards. In this article, we explore the benefits of Precision Machining Manufacturing and the key industries that depend on its capabilities.

1. Advantages of Precision Machining Manufacturing

Precision Machining Manufacturing offers a host of advantages that make it indispensable for high-stakes industries. Here are its most notable benefits:

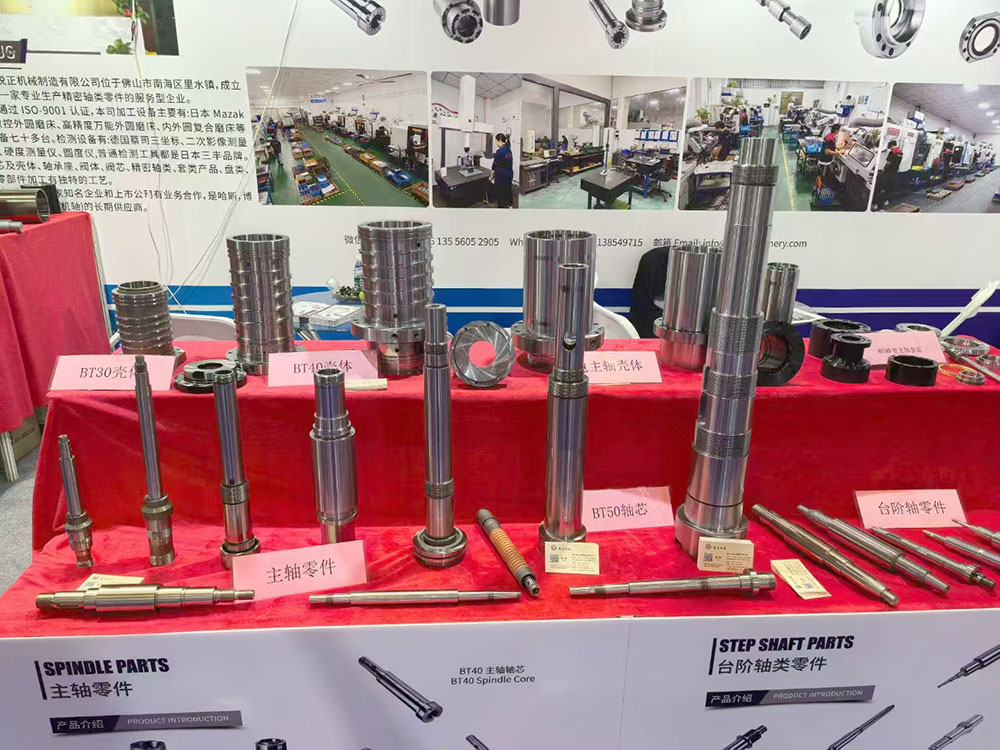

A. Unmatched Accuracy and Consistency

Precision machining utilizes computer-controlled tools like CNC (Computer Numerical Control) machines to produce components with tolerances as tight as ±0.001 mm. This level of accuracy ensures parts fit perfectly in complex assemblies, reducing errors and enhancing product performance.

B. Efficiency in High-Volume Production

Automated processes enable Precision Machining Manufacturing to deliver large quantities of identical parts quickly. This scalability is critical for industries like automotive manufacturing, where speed and uniformity are non-negotiable.

C. Superior Material Versatility

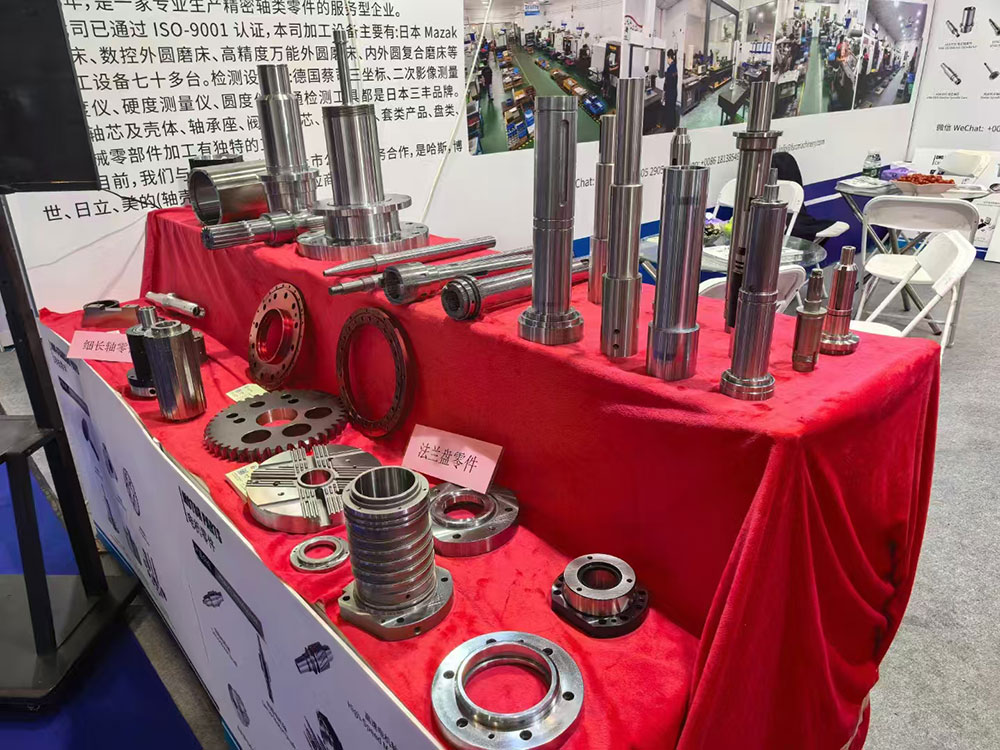

From titanium and stainless steel to plastics and composites, precision machining handles a vast range of materials. This flexibility allows manufacturers to tailor solutions for specific applications, such as corrosion-resistant medical implants or lightweight aerospace components.

D. Complex Geometry Capabilities

Advanced 5-axis CNC machines can craft intricate shapes and features that traditional methods cannot achieve. This capability is vital for industries like energy, where turbine blades or fuel injectors require highly specialized designs.

E. Cost-Effectiveness Over Time

While initial setup costs may be higher, precision machining minimizes material waste and reduces the need for post-production adjustments. Long-term savings in labor, scrap, and rework make it a cost-efficient choice for critical applications.

2. Key Industries Relying on Precision Machining Manufacturing

Precision Machining Manufacturing serves as the backbone of numerous sectors. Below are the industries that depend most heavily on its expertise:

A. Aerospace and Defense

Aircraft engines, landing gear, and satellite components demand absolute precision to ensure safety and performance. Machined parts must withstand extreme temperatures, pressures, and stresses, making Precision Machining Manufacturing a non-negotiable solution.

B. Medical and Healthcare

Surgical instruments, prosthetics, and implantable devices require biocompatible materials and flawless finishes. Precision machining guarantees sterility, durability, and compatibility with human anatomy, directly impacting patient outcomes.

C. Automotive and Transportation

From engine blocks to electric vehicle (EV) battery housings, automakers rely on precision-machined parts for reliability and efficiency. The shift toward EVs further amplifies the need for lightweight, high-performance components.

D. Electronics and Semiconductor Manufacturing

Microchips, circuit boards, and connectors demand microscopic precision. Precision Machining Manufacturing enables the production of miniaturized, heat-resistant parts essential for smartphones, computers, and IoT devices.

E. Energy and Renewable Technology

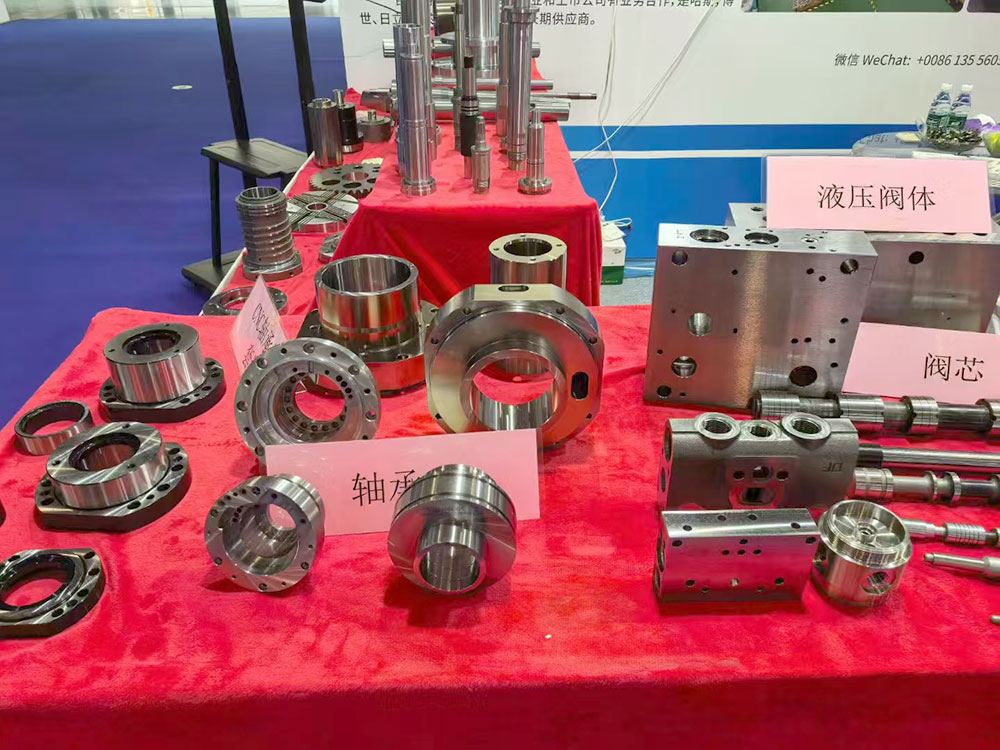

Wind turbines, solar panel components, and nuclear reactor parts require exact specifications to maximize energy output and safety. Precision machining ensures these systems operate efficiently under demanding conditions.

F. Industrial Machinery and Robotics

Heavy-duty gears, hydraulic systems, and robotic arms depend on precision-machined parts to maintain seamless operation in factories and warehouses. Even minor deviations can lead to costly downtime.

The Future of Precision Machining Manufacturing

As industries continue to push the boundaries of innovation, Precision Machining Manufacturing will remain a critical enabler of progress. Its ability to deliver accuracy, versatility, and efficiency positions it at the heart of sectors ranging from lifesaving medical devices to sustainable energy solutions. By partnering with experienced precision machining providers, businesses can stay competitive in an era where quality and reliability are paramount.

For companies seeking to optimize production, investing in Precision Machining Manufacturing is not just a choice—it’s a strategic imperative.