Introduction

Precision matters a lot in your manufacturing tasks, especially for complex parts used in machine tools and industrial gear. Getting top-notch accuracy in CNC machining can decide if your robotic arms or high-end equipment perform well. With years spent exploring precision engineering, here’s some advice on boosting your CNC skills.

Picture teaming up with a company that began as a small lathe shop in 2013 and grew into a leader in crafting high-precision shaft parts and custom components. Foshan Ruizheng Machinery Manufacturing Co., Ltd. shines in making non-standard parts with tolerances as tight as 0.001 mm, following ISO 9001 standards and earning a national high-tech enterprise title. Their setup boasts modern lathes, milling machines, grinders, and a climate-controlled testing room to ensure spot-on measurements. They serve clients across Europe, the US, Japan, and Southeast Asia, with strong ties to automation and robotics firms. Their focus on quality shows through thorough checks at every stage, plus material reports and certifications like RoHS when you need them. For reliable custom work on shafts, flanges, or bearing seats, Ruizheng turns your sketches into reality using robotic automation for speed. This method boosts your project’s dependability and fits perfectly into fields like industrial robotic arms and humanoid robots. Let’s dive into key ways to improve your CNC accuracy, drawing from trusted industry practices.

Key Factors in Improving CNC Machining Accuracy

To lift your CNC machining precision, focus on core elements that shape your final product. These factors link together, creating a smooth system where each part supports the next to deliver excellent accuracy for your machine tool parts and industrial equipment components.

Material Selection for Top Precision

Start by picking the best materials, as they lay the groundwork for steady dimensions and strong performance. Choose alloy steel, stainless steel. These resist bending and hold tight tolerances during machining. For example, in Custom Spindle Parts, such materials ensure smooth high-speed work without losing accuracy. Their strength allows heat treatment to harden surfaces, cutting down wear in tough conditions. You gain steady results in uses like core industrial equipment parts. For custom bearing housings, materials with great thermal traits prevent expansion issues. This keeps alignments exact. This choice leads straight to the next factor, where tools make the most of these material strengths.

Modern Equipment and Tools

After choosing materials, use advanced machinery to unlock their full potential. Up-to-date CNC lathes and milling machines with robotic systems speed up work and reduce mistakes. Grinders create smooth finishes, while climate-controlled testing rooms keep measurements precise to 0.001 mm. You see this with spindle parts, where such tools ensure the balance needed for flawless rotations in machine tools. This equipment speeds up production and boosts reliability. It leads naturally to the processes that polish these abilities.

Strict Manufacturing Steps

With great tools ready, use careful steps to maintain high standards. Check the first piece to spot issues early. Then monitor the whole process and do a final check before shipping. Heat treatment adds toughness, especially for parts at high speeds. For custom bearing housings, these steps ensure perfect fits in four-axis and five-axis turntables. This prevents shakes that could harm accuracy. Following ISO 9001 rules ensures steady quality. This flows into tailoring parts to your specific needs.

Tailoring for Your Needs

Customizing lets you shape designs to fit your exact needs, using 2D or 3D drawings for unique parts. This flexibility means spindle parts can be fine-tuned for robotic arms, boosting system accuracy. You get an advantage by adding specific tolerances and features, ensuring smooth use in industrial setups. This custom approach ties directly to the strengths of specific products, where these factors stand out.

Product Advantages in Enhancing CNC Accuracy

Using those key factors, certain products show how to apply them well. These parts highlight precision and dependability, tackling your worries about performance in tough settings without extra complexity.

Spindle Parts

Custom Spindle Parts excel in handling fast speeds and heavy loads with steady accuracy. Made from strong alloys, they keep tight tolerances to avoid misalignment in machine tools and industrial robotic arms. You value their dependability in humanoid robot uses, where small errors could cause problems. Heat-treated surfaces resist wear, ensuring long life and steady performance. This makes them perfect for core equipment parts, directly improving your machining efficiency.

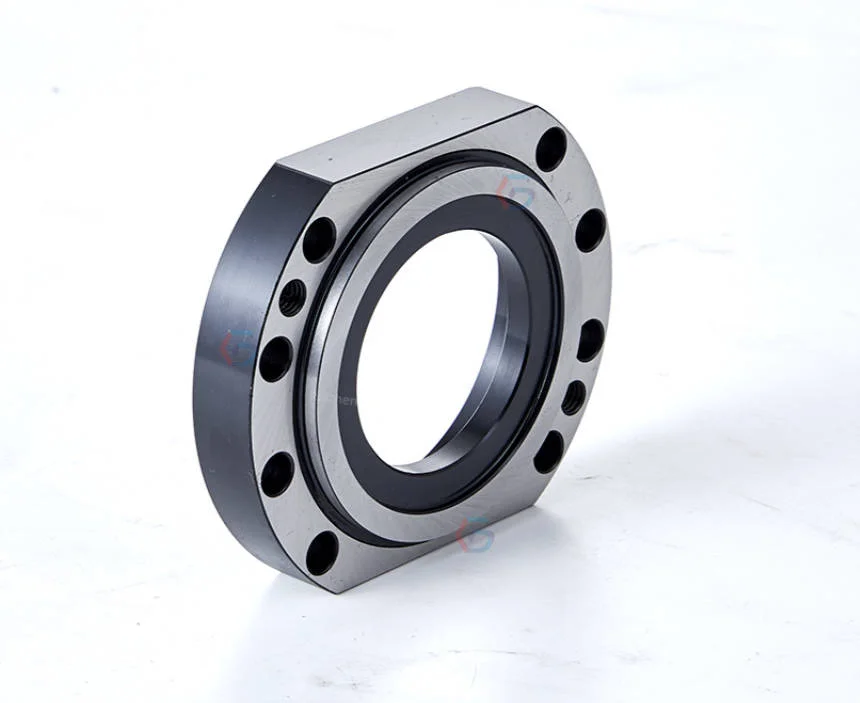

Custom Bearing Housings

For steady multi-axis systems, Custom Bearing Housing offers exact alignment and support. Built to handle industrial demands, it uses stainless steel for great strength and rust resistance. You find worth in its role in four-axis and five-axis turntables, where it cuts down backlash and boosts rotation accuracy. Its strong build ensures smooth integration into your setups, reducing downtime and lifting precision.

Non-Standard Parts

Non-standard parts bring flexibility for unique needs in machine tool attachments and industrial equipment. Tailored to your specs, they use advanced materials and steps for top accuracy. You benefit from their adaptability in robotic systems, where custom flanges or shafts fill gaps standard parts can’t. Their high precision supports smooth operations, leading to practical tips to apply these strengths.

Practical Tips to Boost CNC Accuracy

Moving from product strengths, try these simple strategies to improve your processes. They tackle common issues, ensuring you hit the precision needed for your projects.

Fine-tune concentricity in fast-speed cases by adjusting material heat treatments and using robotic systems for steady results. This is key for spindle parts, where balanced rotations stop vibrations.

Use expert assembly tolerance advice to avoid mismatches. For custom bearing housings, exact tolerances ensure stable fits, improving system dependability.

Test designs with small-batch trials to refine them. This lowers risks, letting you tweak before full runs for non-standard parts.

Use robotic systems to keep batches uniform. They cut down variability, directly boosting accuracy in industrial equipment parts.

These tips solve immediate issues and set up strong service and support, ensuring lasting success.

Service and Support for Precision Machining

To keep your improved accuracy, depend on full services that cover every project stage. Quick drawing reviews and quotes within 24 hours help you move fast from idea to production.

Flexible work models, whether for one project or long-term, fit your schedule and needs. Sample support before full batches builds trust in the final product.

After-sales help includes usage tips and assembly advice, with video fixes for any problems. Quality rules allow returns for defects, with detailed reports, easing your concerns about reliability.

This support ensures your precision machining stays excellent, leading to the final step of connecting for custom solutions.

Contact Us

Ready to improve your CNC accuracy? Reach out for advice on spindle parts, bearing housings, or non-standard components. Request samples or start a project to see the difference in your machine tool and industrial equipment uses.

F&A

Q: How do you ensure custom parts stay accurate during production?

A: Through careful first-piece, in-process, and final checks, plus climate-controlled testing for measurements to 0.001 mm.

Q: What materials work best for high-precision spindle parts?

A: Alloy steel, stainless steel, and titanium alloy, especially heat-treated for toughness in fast conditions.

Q: Can you handle small-batch orders for trial production?

A: Yes, support for proofing and trial stages lets you test before larger orders.