The bearing housing, frequently viewed merely as a simple metallic shell, stands as unquestionably one of the most essential components in any rotating system. It supplies the fundamental support, extreme accuracy, and essential protection required for the bearing to achieve its intended lifespan and peak performance. Within the demanding environment of industrial machinery, machine tool accessories, and highly specialized equipment like engine parts for ATVs, UTVs, or snowmobiles, relying upon generic components is a considerable risk. The optimal strategy for guaranteeing maximum system dependability and efficiency involves the expert engineering of a custom bearing housing.

Introduction: The Paramount Role of Custom Bearing Housings

In critical industrial applications—ranging from compressors and general purpose machinery to specialized outboard engine accessories such as those employed on yachts and other vessels and industrial robots—the malfunction of a housing can precipitate significant operational stoppages. The housing furnishes structural integrity, maintains shaft alignment, and offers environmental defense, all of which are absolutely critical for maximizing the bearing’s performance.

Why Ready-Made Solutions Often Fail in Rigorous Applications

Standard bearing housings are engineered for broad appeal, which inherently involves design concessions that are often unsuitable for specialized tasks. When your machinery operates at the boundaries of performance, these concessions rapidly transform into liabilities. The most prominent source of error is The need for precision. Standard housings commonly lack the micron-level tolerances and geometrical accuracy necessary for equipment like electric spindles or balancing machines where runout must be minimized. This insufficient tolerance leads to untimely bearing fatigue and expensive vibrations. Furthermore, numerous applications encounter Unique operational challenges. Consider the severe temperatures in deep well products or the persistent contamination faced by mine motors and equipment utilized in the petroleum industry. Standard designs are simply incapable of providing the essential durability against these abrasive, high-load, or corrosive settings, rendering customization imperative.

Phase 1: Determining Design Prerequisites and Specifications

Crafting a custom housing is not merely a task of resizing a generic component; it is a thorough engineering process that commences with an in-depth examination into the machine’s operational environment. Each design decision, from material selection to seal choice, must be directly attributable to a specific operational need. This foundational step is a detailed examination of the working conditions—where and how the component will function—as this directly governs all subsequent engineering choices.

Analyzing the Operational Context

A comprehensive analysis must be performed to accurately determine the loads, speeds, and environmental challenges.

- Load and Speed: It is vital to accurately differentiate between radial and thrust loads to determine the requisite wall thickness and stiffness. High rotational speeds (RPM), frequently observed in outdoor drone propulsion systems and high-end engine crankshafts such as those for four-cylinder motorcycles or large-displacement motorcycles, influence the material’s thermal stability and lubrication needs.

- Temperature Profile: The absolute necessity of selecting housing materials and lubrication that can endure continuous operating and ambient temperatures is paramount, as the design must account for thermal expansion to preserve bearing clearance.

- Contamination Protection: Selection of appropriate sealing arrangements (labyrinth, contact, non-contact) is determined on the expected level of contamination, which is particularly important for agricultural machinery or mining applications.

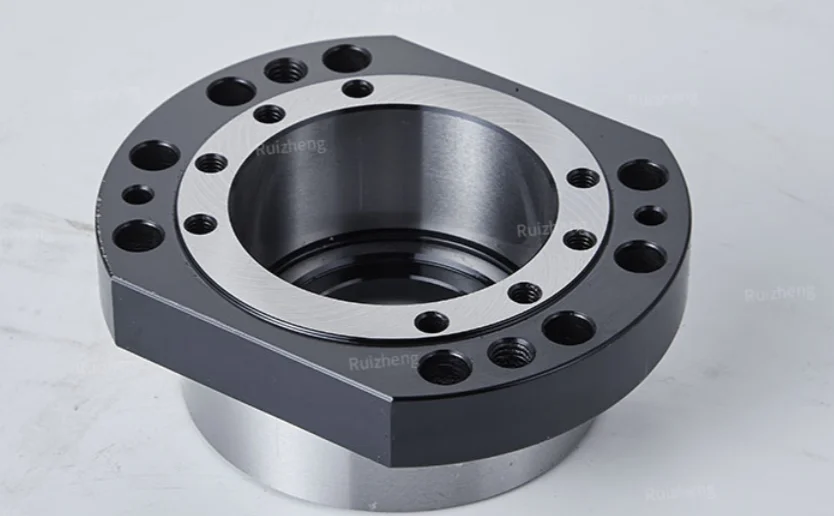

Material Selection: More Than Just Standard Steel

The appropriate choice of material is pivotal to the housing’s long-term performance and protection. It must provide the required strength and stability under operating conditions. While Common Materials like cast iron, aluminum, and stainless steel suffice for most purposes, rigorous applications often mandate Specialized Materials. This involves high-strength alloys or non-metallic options for unique needs, such as lightweight or non-magnetic requirements in certain robotics or unmanned system applications. The final protective layer is the Surface Finish and Coatings. Given the frequently-harsh industrial environment, the significance of coatings (e.g., galvanizing, specialized painting) for corrosion and chemical resistance, especially for marine hardware and outboard engine components, cannot be overstated. Opting for the correct material and guaranteeing the required dimensional accuracy throughout the machining process is where genuine experience becomes paramount. You can investigate our dedicated custom bearing housing processing service to see how the company, Ruizheng, manages these complex material and tolerance requirements.

Phase 2: Fundamental Design Elements of the Housing

Once the operational prerequisites are established, the design progresses to the physical shape and features that directly interact with the bearing and the external environment. This stage concentrates on precise fitting and system integration. The housing’s design must impeccably translate the theoretical specifications into a functional component that supports the bearing under dynamic conditions.

Bearing Seat and Bore Tolerance

The housing’s primary purpose is to secure the bearing. The achievement of this function depends entirely on maintaining exceptionally close tolerances.

- The Fit: The essential relationship between the bearing bore tolerance and the housing seat must be perfect to avoid creep, slippage, or crushing the bearing.

- Machining Precision: Stresses the need for specialized precision engineering services to attain the required tolerance levels.

Machining Precision A reliable custom housing necessitates machining methods that extend beyond standard capabilities. This includes grinding and turning with micron-level control to ensure the inner bore is perfectly round, perpendicular, and concentric with the mounting surfaces, which is especially essential for preserving the performance of high-end engine components like those utilized by manufacturers such as BMW or Harley-Davidson.

Features for Mounting and Alignment

Correct installation and alignment are fundamental to maximizing bearing life. The housing design must enable this through thoughtful feature placement.

- Bolt Hole Configuration: The design of the bolt hole configuration must assure the appropriate distribution of mounting forces across the housing base to preclude distortion.

- Alignment Tools and Features: The incorporation of specific guides, keyways, or datum surfaces permits for precise and repeatable installation, critical for minimizing vibration in industrial applications. For components that demand extraordinary strength and soundness, such as specialized high-load bearing seats, we concentrate on material integrity and detailed finishing.

Integration of Lubrication and Cooling Systems

A custom housing functions as the container for the lubrication and cooling required to manage the heat produced by the bearing under load. This proactive management is indispensable for extended component life.

- Oil Circulation/Sump Design: Efficient oil circulation/sump design is often overlooked. The housing must incorporate channels or reservoirs optimized for effective oil bath or circulation lubrication, guaranteeing constant flow and preventing lubricant stagnation.

- Cooling Jackets: For high-speed applications, proactive heat management is required, which means engineering cooling circuits into the housing to actively dissipate heat away from the bearing and housing structure.

Phase 3: Manufacturing Considerations and Quality Control

Even the most carefully designed housing can fail if the manufacturing process is flawed. Precision engineering requires adherence to rigorous quality control protocols from the initial raw material selection to the final dimensional inspection. The selection of the manufacturing route must be justified by the required precision and scale of the final component.

Choosing the Appropriate Manufacturing Process

The determination of the manufacturing method significantly impacts the final cost and dimensional stability of the housing.

- Casting vs. Machining: The decision must evaluate the pros and cons of each method based on volume, complexity, and, most importantly, the required precision for parts used in marine engine components or spring machines.

- Post-Processing: The significance of heat treatment, stress relief, and final grinding to assure dimensional stability and preclude warpage after machining is critical for maintaining the tight tolerances of industrial machine accessories. Our dedication to high performance encompasses thorough material processing and testing, making sure components are prepared for the most demanding applications.

Critical Inspection Points

Quality control furnishes the necessary guarantee that the design specifications have been physically achieved, verifying the soundness of the component before it enters the supply chain.

- Dimensional Inspection: Inspection must concentrate on bore concentricity, perpendicularity, and parallelism—the geometric relationships that directly affect bearing performance and are crucial for the stability of robotic components like harmonic reducers.

- Non-Destructive Testing (NDT): Employing NDT is recommended for highly stressed or critical components to identify internal flaws, cracks, or material inhomogeneities that could lead to premature failure in equipment such as heavy-duty engine parts.

Partnering for Success: Why Ruizheng is Your Reliable Manufacturer

Choosing the appropriate manufacturing partner is equally important as the design itself. A partner with demonstrated experience in precision industrial components will ensure your custom design transitions smoothly from blueprint to high-performing hardware.

Ruizheng’s Expertise in High-Precision Components

resides in manufacturing specialized, high-tolerance parts like custom bearing housings and shafts for discerning B2B clients globally. We comprehend the fine margins required in high-speed and heavy-load machinery across various sectors, including marine and general industrial applications. Our Commitment to Quality is supported by a rigorous QC process and the capability to handle complex materials and specifications. Our emphasis on aftermarket service makes us a dependable source for replacement parts and one-stop procurement for repair companies and factories. Contact us to discuss your unique bearing housing requirements and see how our engineering team can support your next project.

Conclusion: Investing in Optimized Performance

A specially crafted bearing housing is much more than just a basic metal enclosure. It serves as a smart investment in the reliability, effectiveness, and prolonged durability of your entire mechanical setup. B2B clients can greatly cut down on ongoing repair expenses and unexpected stoppages by carefully evaluating the working conditions, material choices, and production accuracy. This thoughtful method ensures that your equipment runs exactly as planned, even under tough circumstances. Team up with a skilled provider like Ruizheng to turn your strict requirements into a top-notch, real-world item that offers the best possible working benefits.

FAQ

Q1: How does a custom housing design contribute to longer service life in rotating machinery?

A: A custom housing provides exact shape matching and solid stress spreading. Precise cutting almost completely avoids shaft misalignment and focused stress spots, which are main causes of bearing and shaft wear. The design cuts down extra friction and shaking. As a result, it greatly boosts the average time between breakdowns in key spinning parts, like engine crankshafts or precise robotic connections.

Q2: What advantages do advanced materials provide in custom bearing housings?

A: Specially made materials offer better protection against harsh surroundings and better heat control than regular metals. Top-quality types improve rust resistance in rough sea environments. They also keep size steady in very hot or cold settings common in fast-spinning spindles. Thus, they maintain steady performance and output in tough uses.

Q3: Beyond production, what additional expertise does a specialist like Ruizheng provide during development?

A: A skilled precision collaborator offers deep Design-for-Manufacturability (DFM) advice right from the start. Using our internal cutting skills, we suggest specific changes to clearances, shapes, or surface finishes. These tweaks reduce making costs, ease putting together, and speed up delivery times. At the same time, they keep full working ability and part strength intact.