img.How Shaft Machining Affects the Best Material Choice for Drive Shafts.webp

Picking the right stuff for drive shafts hinges on how simple it is to shape. This changes how well the shaft works, how much money it takes, and how quickly it can be built. Precise Shaft Machining makes sure sizes are spot-on and surfaces are sleek. This stops wobbling and wear in parts that move. Strong stuff like steel or light aluminum blends toughness, long life, and easy shaping. Heat treatment makes parts tougher. Ruizheng gives custom, super-accurate shaft solutions (down to 0.001mm exactness) for many industries. They use stuff like steel, aluminum, and titanium, made for strength, low weight, or rust-proofing. Their skills cover CNC Shaft Machining, heat treatment, and sticking to worldwide quality rules, helping big machines, robots, and light motion setups.

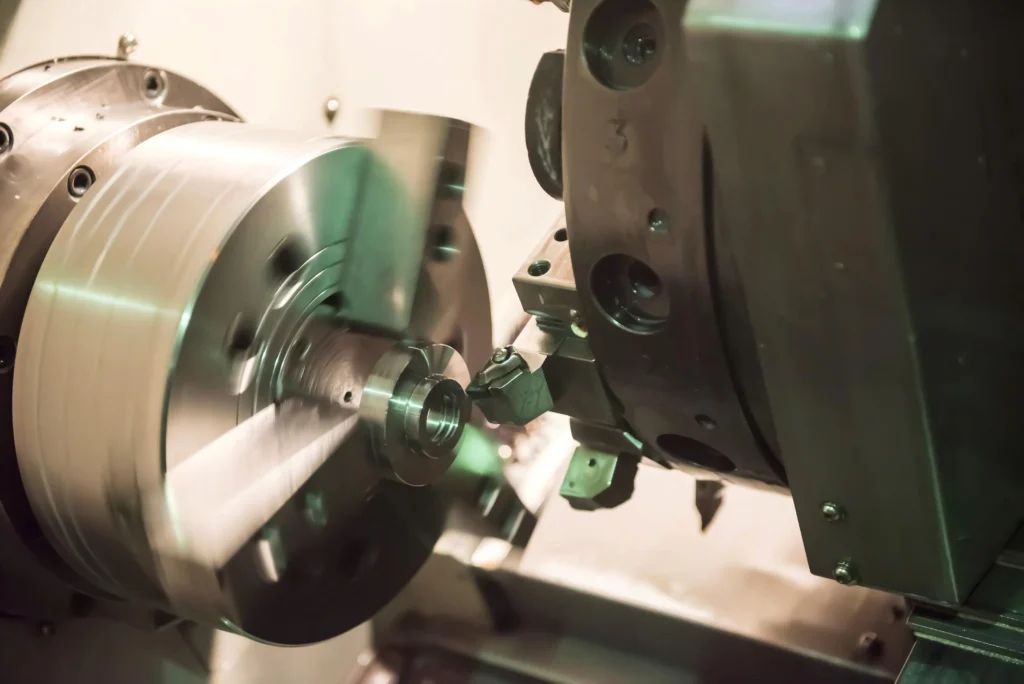

What Role Does Shaft Machining Play in Drive Shaft Design?

Shaft Machining is key to making drive shafts that run well. It forms parts to fit just right and move smoothly. If machining isn’t exact, shafts can shake or break down fast. Ruizheng uses top-notch methods to make sure every shaft is trusty and solid.

Why Is Machinability So Critical When Selecting Materials for Shafts?

Choosing a material for a drive shaft means thinking about how easy it is to cut and shape. This affects how good the shaft is, how long it takes to make, and the price. For instance, some tough steels are sturdy but hard to work with. This can slow things down and cost more.

Ruizheng, based in Foshan, is great at precise Shaft Machining and custom parts. They pick materials that are strong and simple to form. Medium-carbon alloy steels or certain kinds are common because they shape nicely. This gives exact sizes and smooth surfaces.

How Does Machining Precision Affect Dimensional Accuracy and Surface Quality?

Shaft Machining is super important for getting the right size and finish on spinning parts. A badly made shaft might wobble, vibrate, or hurt other bits like bearings. Tools like CNC turning, grinding, or milling hit tiny tolerances, as small as 0.001mm.

This exactness makes shafts round, centered, and slippery-smooth. It matters for fast-spinning or heavy jobs, like spindles in machine tools or joints in factory robots. Good machining keeps things running well and lasting long.

img.spindle.webp

Can Machining Alter the Mechanical Properties of Shaft Materials?

Yes, Shaft Machining does more than just shape things. It can mess with the material’s insides. Too much heat from tools could make tiny cracks or stress, which might make a shaft last less. That’s why heat treatment is used during machining.

Ruizheng uses stuff like alloy steel, stainless steel, and titanium alloy, and they do heat treatment. By mixing careful machining with heat treatment, they make shafts harder (HRC), stronger, and more wear-proof. This keeps shafts tough and steady in size.

What Are the Key Performance Metrics When Choosing Drive Shaft Materials?

Why Do Torsional Strength and Fatigue Resistance Matter So Much?

Drive shafts deal with twisting forces all the time. They need to stop cracks and stay strong over lots of cycles. Torsional strength lets them handle twisting stress. Fatigue resistance keeps them from breaking after long use.

Medium-carbon alloy steels, made tougher by heat, are used a lot in factory gear. They stay solid for millions of cycles. Ruizheng is great at custom machining of non-standard shafts, flanges, bearing seats, and other exact parts. These go in machine tools and big industrial gear where breaking is bad news.

How Do Weight and Rotational Inertia Influence Performance?

In things like spinning tables or robot arms, lighter shafts move quicker and save power. Aluminum alloys are awesome because they’re light but still strong. But they need super-precise Shaft Machining to stay stiff and lined up.

Shaft Machining finds a balance between weight and strength. Designs like hollow middles or sloped shapes cut extra stuff while keeping shafts solid. This makes them work better without losing toughness.

Is Corrosion Resistance Important in Industrial Settings?

Yes, especially in spots with water, oils, or strong cleaners. Stainless steel stops rust well, but is harder to machine than carbon steel or aluminum. Ruizheng’s products follow European and American quality rules. They give material reports, size check reports, and RoHS papers if you ask. This makes sure shafts do great, last in rough spots, and meet global standards.

Which Materials Are Commonly Used for Drive Shafts—and How Well Do They Machine?

Are Steel Alloys Still the Go-To Material for High-Strength Applications?

Yes, for good reasons. Medium- to high-carbon alloy steels are strong and don’t cost too much. They also take well to heat treatment, which makes them harder (HRC) and tougher for a long time. These steels fit most Shaft Machining ways, like turning or grinding.

But some steels are tough to machine. Types with sulfur cut more easily but might not be as strong. You pick based on whether strength or easy machining is more important.

When Should You Consider Aluminum Alloys Instead?

Aluminum alloys are great when you want a light shaft that’s still pretty strong. They’re easier to machine than most steels because they don’t need as much cutting force. This makes them perfect for fast test parts or small custom batches.

But aluminum wears out quicker under big loads. It’s best for lighter tasks unless the design adds extra help.

What About Composite Materials? Are They Worth It?

Composites like carbon fiber are super strong for their weight. But they’re hard to machine with normal tools, cost a lot, and don’t work well in regular factories. They’re also tricky for small, custom industrial parts.

Composites are good for aerospace or car drive shafts, which Ruizheng doesn’t make. For normal factory parts, they’re usually not practical because of machining problems.

How Do Different Machining Techniques Influence Material Performance?

What Effects Do Turning, Milling, and Grinding Have on Final Properties?

Each machining method affects the material differently:

- Turning keeps shafts centered but might leave small tool scratches.

- Milling makes fancy shapes but can add stress to the stuff.

- Grinding gives a super-smooth finish, perfect for bearing spots.

When done in controlled places, like rooms with steady temperatures, these methods give great performance and easy fitting.

Why Integrate Heat Treatment During Machining Instead of After?

Doing heat treatment during Shaft Machining controls hardness better. It stops warping that might happen if you treat a finished part. Ruizheng says: heat treatment can be done. This lets makers harden just the bits that wear while keeping others bendy for fittings or threads.

How Can You Balance Cost With Quality in Shaft Production?

To keep costs down but still have quality, choose a material that fits the job. Use machines, like robot loaders or multi-axis CNC tools, to speed up Shaft Machining. Ruizheng has turned into a modern high-precision parts maker with lathes, milling tools, grinders, steady-temperature check rooms, and robot loading systems.

This cuts worker costs while making every part the same, even for worldwide clients with strict rules.

What Does Ruizheng Offer in Terms of Material Options and Machining Capabilities?

If you want a dependable supplier for custom shafts made for your machines—from big tools to robot joints—Ruizheng is a great choice. Foshan Ruizheng Machinery Manufacturing Co., Ltd. started in 2013, working on high-precision Shaft Machining and custom parts. They’ve grown from a tiny shop to a modern factory with CNC lathes, mills, grinders, and steady-temperature check rooms. These make sure accuracy is down to microns.

img.Quality.webp

They help industries like automation, industrial robots, and even humanoid robots, where being exact is super important. Their clients are in Europe, the United States, Japan, Southeast Asia, and more. Ruizheng has been to shows like EMO in Germany, Metalloobrabotka in Russia, and the Shenzhen Industrial Exhibition, making a strong network of global customers.

Try their High-Performance Alloy Steel Shafts, built for tough spots needing big twist resistance and long life under constant use. They also have lightweight aluminum shafts, perfect for setups where low weight boosts speed and saves power. These keep perfect fit thanks to CNC finishing down to 0.001mm. They work for high-speed, high-load jobs.

Which Shaft Solutions Fit Your Application Best Based on Ruizheng’s Lineup?

For Heavy-Duty Machinery—Why Should You Choose High-Strength Alloy Steel Shafts?

For big machine tools or industrial gear under heavy twisting loads, you need tough stuff carefully checked. All Ruizheng products get first-piece, in-process, and final checks before shipping. Their alloy steel shafts are made for these rough jobs. They offer solid or hollow designs based on what your system needs.

For Lightweight Motion Systems—How Can Aluminum Shafts Improve Efficiency Without Sacrificing Precision?

When speed matters more than raw power—like in pick-and-place arms or sensor mounts—Ruizheng’s aluminum shafts are awesome. They’re light and super exact, great for four- and five-axis spinning tables, industrial robot arms, and humanoid robots. This means faster moves with less strain on motors, all while fitting perfectly.

Need Something Unique? Why Custom Engineering Collaboration Delivers Better Results

Some projects need more than normal parts. They want special solutions from start to finish. Ruizheng is great at making non-standard parts based on customer 2D/3D drawings. Whether you need weird coatings, mixed materials, or size help, they work with you to make your project win from the start.

FAQ

Q1: Can I request custom shaft designs based on my own drawings?

A: Yes. Ruizheng is awesome at making non-standard parts based on customer 2D/3D drawings.

Q2: What’s the typical lead time for high-precision machined shafts?

A: Normal parts take 20–30 days. Fancy precision parts might need 40–60 days, depending on the details.

Q3: Can I get help picking materials based on my application environment?

A: Yes. Ruizheng gives expert tips on materials based on loads, rust risks, heat, and more during project talks.