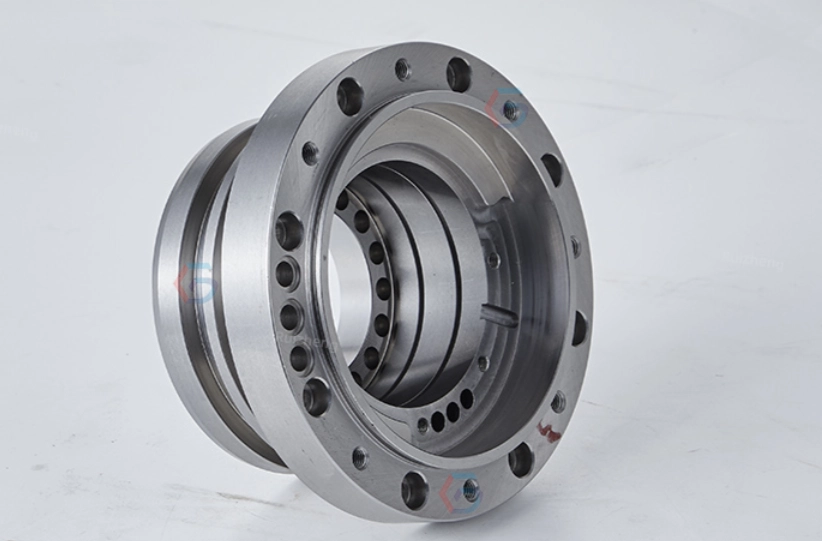

In the busy world of fast-moving parts and heavy factory loads, a bearing seat is much more than just a simple piece of metal. It acts as the very soul of how your machines stay lined up. If you are in charge of busy production lines or creating top-tier equipment, you already know that even a tiny mistake in alignment can cause huge shaking, too much heat, and total system breakdown. The way your Custom Bearing housing is built decides if your machines run with quiet, smooth power or stop suddenly with a very expensive crash.

Precision Engineering: Why Your Choice of Housing Defines Your Success

When you spend money on industrial parts, you are not just buying heavy metal; you are buying peace of mind and steady work time. The link between a bearing and its seat is a very delicate balance of tiny measurements. If the fit is too tight, the bearing cannot breathe and gets too hot; if it is too loose, shaking will ruin the internal parts quickly. This is exactly where super-accurate making becomes your biggest win over your rivals.

The Impact of Geometrical Accuracy

How does a carefully made seat actually put more money in your pocket? It all starts with being perfectly centered. When a bearing seat is made with a precision of $0.001mm$, it makes sure the middle of the spinning shaft stays totally still. For you, this means:

- Longer Part Life: Less rubbing means your bearings stay good for a much longer time before you have to buy new ones.

- Saving Power: A perfectly straight shaft takes less force to turn, which cuts down the electricity bill for your industrial motors.

- Less Noise: Stopping tiny shakes makes the workplace much safer and nicer for the people working there.

Material Strength and Heat Control

Your machines often have to work in very tough spots, from fast-turning machine tool parts to heavy robotic arms. The material you pick for your bearing seat must stay in its right shape even when it gets hot. By using top-quality alloy steel and stainless steel together with expert heat treatment (HRC), a well-built housing keeps its strong shape even under very heavy weight. This stops the “sticking” of parts that usually happens when cheap materials grow at different speeds than the bearing when they get warm.

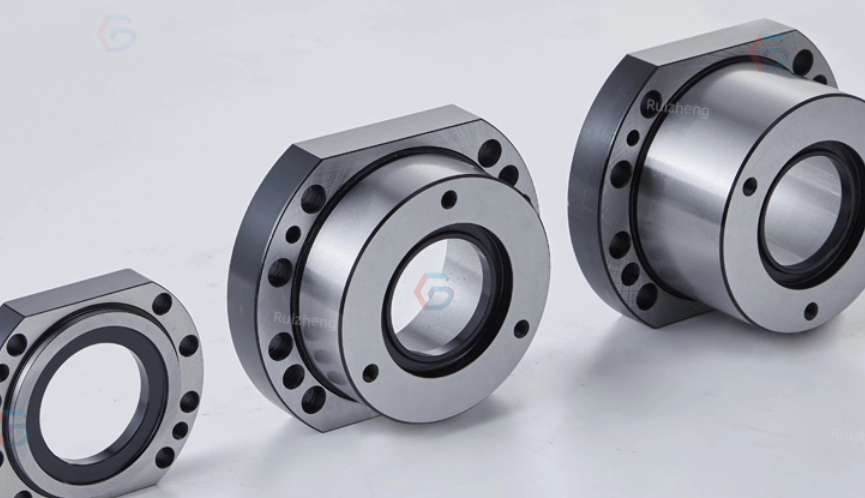

Beyond the Part: A Partner in High-Precision Manufacturing

Finding a shop that can just read a drawing is quite easy; finding a true partner who cares about your win as much as their own is very rare. This is why Ruizheng stands out from the crowd. Started in 2013, they have grown from a small shop with a few tools into a very smart, high-accuracy maker. They focus on making special shafts, flanges, and bearing seats that are the heartbeat of modern factories today. Whether you are building industrial robotic arms, new types of robots, or main parts for heavy machinery, their team joins your work to make sure every tiny bit is perfect. By strictly following the ISO 9001 quality rules and using a special room with a steady temperature, they promise that the part you get is exactly what you asked for in your 2D or 3D drawings.

Solving Your Real-World Challenges through Custom Design

Standard parts you buy from a catalog often fail to meet the special needs of unique factory machines. You need answers that change to fit your specific problems, whether those are tight spaces, super-fast speeds, or special ways of holding things together.

Tailored Solutions for Machine Tools and Accessories

In the world of machine tools and big industrial mother machines, the bearing seat must hold up fast-turning parts with zero room for error.

- Better Weight Sharing: Custom builds allow for thicker walls or stronger holding spots where your specific machine feels the most stress.

- Added Features: You can ask for special oil holes or spots for sensors right in the bearing housing build, which makes putting it all together much faster for you.

- Many Uses: These accurate parts are a must for four-axis and five-axis turning tables, where forces from all sides need a very stiff and strong housing.

Reliability for Industrial Equipment and Robotics

As factory robots get more complex, the parts inside their arms and bodies must be light but also very, very strong.

Heavy Weight Power: Custom bearing seats make sure that robot joints move in a smooth way even when they are carrying heavy tools.

Less Fix-it Time: By offering a “one-stop” shop for your needs, your supplier can help you find and install other parts like seals, bearings, and screws, making sure the whole set works as one.

Fast Sample Making: If you are just starting a new project, you can get help with small-batch testing to check your ideas before you go into big production.

Seamless Service: From Blueprint to Installation

A great product is really only half of the story. You deserve a buying process that is just as sharp and clean as the parts you are buying.

Professional Logistics and Documentation

- Dealing with shipping across the world should not be your big worry. When you work with a high-end maker, you get to use a global selling network that reaches Europe, the United States, Japan, andQuick Answers: Get your drawing checks and price lists in your hands within 24 hours.

- Clear Paperwork: Get material lists, size check reports, and RoHS papers whenever you need them.

- Easy Shipping: They help with fast mail, air travel, and sea ships, including DDP (Delivered Duty Paid) services where the work is done for you.

- Easy Talking: If any trouble pops up, you can get help through a video call to show you how to put things together or find out what is wrong.

Southeast Asia.

Quality Assurance You Can Trust

Every single part goes through a very tough checking path: first-piece check, middle-of-the-work check, and a final check before it ever goes into a box. This high level of looking makes sure that the parts you get are ready to be put right into your machine tools or factory gear, saving you the time and the high cost of checking them again yourself.

Take Action: Optimize Your Mechanical Performance Today

The way your bearing seat is designed is like a quiet friend to your machine’s power. Picking a high-accuracy, custom-built housing means you are picking fewer broken parts, lower repair costs, and a much more solid product for your own buyers.

Stop settling for “okay” when your factory gear needs to be perfect. Whether you are creating the next big thing in factory robots or keeping high-speed machine tools running, the right bearing housing is the key that unlocks everything.

Reach out to the engineering team today at https://spindleshaft.com/ and let them turn your drawings into parts that truly perform.

Frequently Asked Questions

Q: Can you produce bearing seats according to my specific 2D or 3D drawings?

A: Yes, we are experts in making special parts based exactly on your technical drawings. We can also help with advice on how parts should fit together to make sure everything works perfectly when you assemble it.

Q: What is the typical lead time for high-precision bearing housings?

A: For normal parts, it usually takes about 20-30 days. For very high-end parts that need more work or special heat treating, it takes about 40-60 days.

Q: Do you support small-batch trial production for new designs?

A: Yes, we definitely do. We enjoy helping during the testing and sample-making stages so you can be sure of your design before you start making a huge amount of them.