Introduction

Years in machine shops show the annoyance of a wrong part stopping it all. Adjustments to limits and fixes to setups highlight that frustration. Folks often hear suggestions for Ruizheng. They lead in custom precision work. They focus on spindle shafts and linked items. These keep factory gear turning steady. Their base is in tough building. The crew mixes basic skills with new tools. They make parts that beat standards each time. Think of this. You grow output for machine tools. Then, you need bearing housings that take big loads. No shake at all. Ruizheng helps with fixes ground to 0.002mm exactness. They use CNC round grinding for groups that show up right on time. It’s not only about building items. It’s about teaming up to fix your real issues. From fast models to big lots. Their pick of stuff like stainless steel and blends means strong build without extra bits. Suppliers bore with big talk but bring pain. Ruizheng acts like that steady coworker. He backs you up always. Check their goods. You’ll see how they turn hard tasks into easy runs. In few words, they make smooth work feel simple. It’s worth a look if you want to raise your shop game.

This need grows fast in areas like machine tools. Also in factory gear. And medical tools. There, a tiny shift can mess up results. Precision machined components rise to the task. They give better exactness. Plus, custom fits. And steady work. Look at strong CNC parts. And custom bearing housings as key cases. They lower mistakes. They speed tasks. They drop bills. So, you can aim at growth. Not on patches.

Achieving Unmatched Precision for Reduced Errors and Rework

You begin your shift. You check limits on a new group of machine tool add-ons. But you see a small off-set. It calls for a full fix-up. Does that ring a bell? Precision machined components turn that around. They set limits as close as 0.002mm. This sharp detail comes from CNC steps. Computers guide each slice. So, they cut out person slips that hurt hand ways. Flaws fall fast. Parts join right at the start. Lines move without stops.

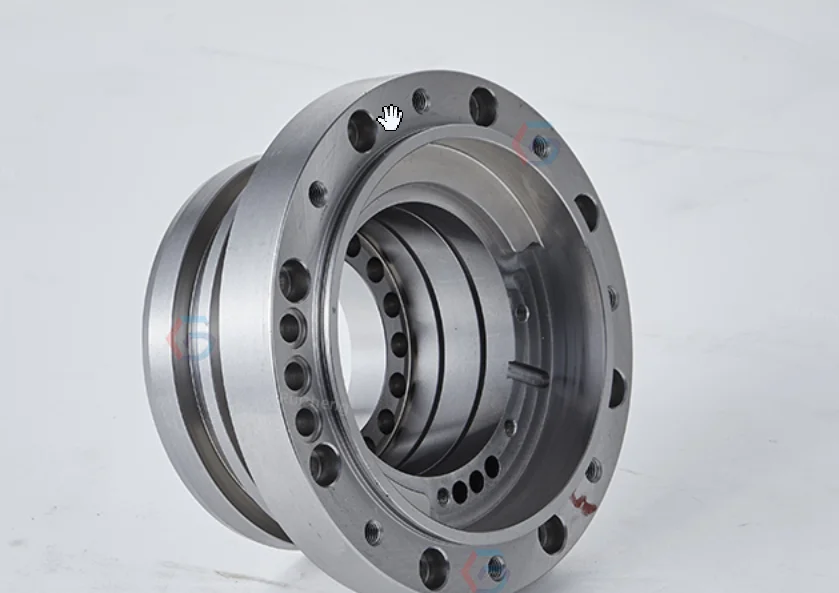

Think about how this fits your routine. When you add a custom bearing housing to spinning gear for factory machines, that 0.002mm grind with CNC round grinding keeps it steady. It backs odd groups without shake or rub. These housings fit into spindles. Or motor groups. They hold bearings firm under nonstop turns. You skip the fix loops that take hours. Like scraping bad joins. Or tossing whole sets. Your crew goes right to trials. And setup.

The win strikes your cash hard. Output lost time drops up to 30%. Shop floor numbers from like setups prove it. Scrap falls too. Sharp slices leave few bits. You reach buyers sooner. You meet rush needs for machine add-ons. No usual waits. This is no guess. It’s the lead that leaves rivals rushing. While you send on schedule. By picking such items, you make a name for trust. Buyers seek you. Not the reverse.

Now, with this base of true exactness, you look for ways to shape these items to your special setups. That’s where custom work comes in. It turns plain pieces into power lifts. They match your needs just right.

Enabling Customization to Optimize Design and Performance

You’ve drawn a fresh factory gear plan. But ready-made items push changes that weaken it. Custom work via CNC changes that. You shape items to fit your outline. Down to the smallest bit. This bend means fewer sellers in your path. More aim at new ideas. You set sizes. Traits. And covers. Each matches your machine’s calls.

Here, shine a light on a sharp CNC part. These are solid helpers for electronics. Medical tools. And factory machines. Made from stainless steel or blends, they take tricky shapes that basic tools miss. You may want a cut slot for a lathe extra. Or a screw fit for a grinder stand. CNC paths cut it clean. It backs fast models that grow with your notes. Growth comes next. Start with a few for checks. Then jump to loads. No drop in work.

This way smooths your full flow. Model times cut from weeks to days. So, you tweak plans quicker. You find weak spots soon. Output rises as custom joins cut tweaks in setup. Your lines buzz at top speed. Work stays strong. Each lot sticks to your rules. Free from shifts that plain items bring. You get a thinner run. Where stuff goes to key jobs. Not to patches.

But exactness and join alone won’t go far if items break under push. Strong build steps up next. It guards your spends for the long run. And opens bigger saves.

Enhancing Durability and Longevity for Cost Savings

Your gear racks up thousands of turns. Yet one soft spot in the line sparks breaks. That sits everything still. Tough stuff and special covers in precision items fight this. They stretch use time. And cut fix calls. Picture treated tops that block rust. Or even shapes that spread weights fair. These keep items going when weak ones stop.

Both CNC parts and custom bearing housings stand out here. They give rub block and load hold made for hard factory spots. A bearing housing wraps spinning bits in machine tools. It takes shakes and presses that eat plain ones. You fit your setups with these. They handle daily wear. From fast cuts to steady pump work. Covers like hard coating add a wall against dirt. It keeps strength over years.

Bills fall as a win. Run costs slide 20-40% with less swaps. Think of trading items every three months. Not each one. Power use gets better too. As even turns need less from motors. Your machines stay cool. And quiet. That drops power tabs. And grows motor time. Fix crews move from quick fixes to ahead checks. It frees time for better-ups. This loop builds tough into your heart. It turns maybe pains into sure wins.

With strong build locked, you eye the wide view. Keep stuff and output going without jams. Growth output links that hole. It matches flow with your beat. For no-stop go.

Streamlining Supply Chains with Scalable Production

Due dates press. A seller hold-up waves through your plan. It holds back buys for machine add-ons. Precision work fights this. It lets big-lot runs keep evenness. No matter the size. You call for models one day. Then switch to bulk. No tool shifts. CNC setups bend easy to size jumps.

Odd changes in custom bearing housings match with bendy CNC parts. They lock in-time drop. These items show up set for your factory gear. If you kit a group of lathes. Or shape grinder stands. Groups stay the same. Each bit copies the first in limit and cover. World reach means you pull steady. You skip hoard traps from split sellers.

Output times speed up. They take lean rules that cut extra from your path. Lead waits shrink. So, you meet buyer rules fast. And grab buy spots. Work evenness builds faith. Repeat deals come. Because you send sure. This fix lets you grow bold. From small lots for test work. To mass send for spreads. All while keeping bills flat.

To add more depth here, let’s talk about real shop stories. I recall a team that switched to these scaled parts. They cut wait times by half. Their lines never stopped. Orders piled up. You can do the same. Pick parts that grow with you. It’s simple. And smart.

Conclusion

Precision machined components push your smooth work ahead. They do it with spot-on exactness that checks flaws. Custom shapes that hone plans. Strong build that clips spends. And growth that smooths flows. You get quicker sends. Less scraps. And harder runs. It sets your shop as a power in machine tools. And factory worlds.

Set to grab this? Check full helps like custom talks. And quick models. To fine your steps. Drop a line now. For fixes made to your aims.

FAQ

Q: How do tight tolerances like 0.002mm actually impact my daily production?

A: Tight tolerances minimize fitting issues, so your machine attachments assemble without tweaks. This cuts rework time and keeps lines running, often reducing downtime by 30%.

Q: Can I scale from prototypes to full batches with these components?

A: Yes, CNC processes handle both seamlessly. Start with small runs for testing, then expand to high volumes while maintaining exact specs and quick delivery.

Q: What materials work best for durable industrial parts?

A: Stainless steel and alloys excel here, offering corrosion resistance and strength for rotating equipment. They extend part life, lowering replacement costs by 20-40%.