spindle part are key components in various industrial applications, especially in the fields of machining, automotive, aerospace and robotics, where spindle part play an extremely important driving mission.

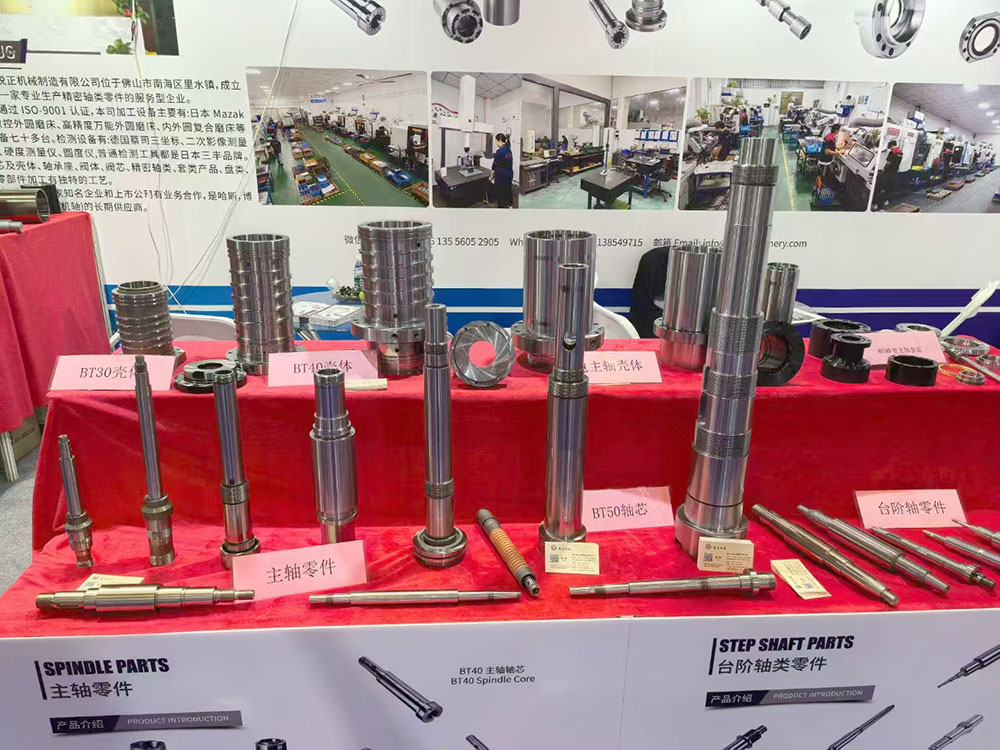

At Foshan Ruizheng Machinery, we produce a large number of various spindle part for customers every year, among which Custom spindle part are required by many customers, mainly reflected in precision, wear resistance, durability and compliance with corresponding models. Custom spindle part processing services can meet industries that require specialized designs, materials and tolerances to meet unique operating needs.

Understanding spindle part

spindle part are mechanical parts used to support and rotate cutting tools, grinding wheels or workpieces in machines such as lathes, milling machines and CNC equipment. Their performance directly affects machining accuracy, surface finish and operating efficiency.

Main characteristics of spindle part:

Since spindle part are important components in mechanical operation, they naturally need to have strict and reliable characteristics, including high precision, durability, thermal stability and balanced design.

High precision: The spindle must maintain strict tolerances to ensure smooth rotation and minimal vibration.

Durability: They are often subjected to high speeds, heavy loads, and continuous operation, requiring strong materials such as alloy steel, stainless steel, or ceramic.

Thermal stability: The spindle must resist deformation under the heat generated by friction and high-speed rotation.

Balanced design: Proper dynamic balancing is critical to prevent vibration that can reduce machining quality.

Custom spindle part machining

Custom spindle part machining involves designing and manufacturing spindles for specific applications. Unlike standard spindles, custom variants are optimized for unique operating conditions and include:

Special dimensions (length, diameter, taper angle)

Material selection (hardened steel, titanium, or composites for extreme conditions)

Bearing configurations (angular contact bearings, hydrostatic bearings, or air bearings for high-speed applications)

Cooling mechanisms (internal coolant channels or thermal compensation systems)

Manufacturing techniques

Production of high-quality custom spindle part requires advanced machining processes, including:

CNC turning and milling: to ensure dimensional accuracy and fine surface finish.

Grinding: to achieve tight tolerances and smooth bearing surfaces.

Heat treatment: to increase hardness and wear resistance.

Dynamic balancing: to reduce vibration in high-speed applications.

Of course, in addition to these basic manufacturing technologies, more advanced machining equipment and testing equipment are needed, as well as a team of experienced and skilled processing personnel. Only with the combination of these factors can better quality Custom spindle part be produced.

Application of Custom spindle part

Custom spindle part are widely used in many industries, including automotive, aerospace, medical equipment, and robotics. Custom spindle part play an extremely important role in these industries, which also leads to strict and demanding requirements for Custom spindle part in terms of design, materials and processing technology.

Custom spindle part processing ensures optimal performance in specialized industrial applications. By utilizing advanced processing technology and material science, manufacturers can produce spindle part that meet strict standards of precision, durability and efficiency.

Whether it is high-speed CNC operation or heavy industrial use, customized spindle part solutions play a vital role in modern manufacturing.