Why Bearing Housings Matter in High-Performance Machinery

Every industrial machine depends on smooth movement. But behind each steady turn, there is a part that people often overlook: the bearing housing. It serves as more than just a shell. It acts as a key piece in your equipment’s overall working life. If you deal with fast-spinning setups, such as those in CNC machine tools, semiconductor equipment, compressors, pumps, or robotic joints, bearing housings play a vital role.

They hold the right spot and back up rotating shafts. This helps cut down on bending and lowers the chance of early breakdowns. Even better, they manage straightness and block out dirt. As a result, they boost the life of the bearing and cut back on sudden stops in work. This leads to better machine trust and less upkeep cost.

Even tiny off-center issues can spark shaking and warmth buildup. Over time, this causes major damage. That is why careful work in bearing housing setup stands as your strongest shield.

What Makes a High-Quality Bearing Housing Essential for Your Operation

When your machine’s output is at stake, good quality is a must, not an extra. A well-made bearing housing cuts down shaking and boosts system output. This not only steadies daily runs but also keeps other parts, like shafts and couplings, free from odd strain.

Yet careful fit is not the only key point. Picking the right materials counts just as much. In tough spots where machines run fast or carry big weights, strength against heat, chemicals, or physical force is a must. We handle many materials like cast iron, ductile iron, carbon steel, stainless steel, aluminum alloy, and special alloys. We pick each one to fit your exact setup needs.

On top of that, made-to-order options are not just nice to have. They are often required. Off-the-shelf housings usually do not match the space or job limits of modern factory systems. Be it a special base for a robotic arm or extra cover for areas prone to rust, custom fixes beat plain ones each time.

Exploring the Main Types of Bearing Housings

Picking the best bearing housing goes beyond simple size match. It is about the job it does. Below are the key kinds often used in factory work:

Split Plummer Block Housings

These find wide use in tough systems because of their split build. This setup makes setup and fixes easier without taking apart the shaft. They pair well with spherical roller bearings to manage big side loads and allow for shaft off-center fixes.

Best for:

- Mining conveyors

- Large-scale compressors

- High-load spindle assemblies

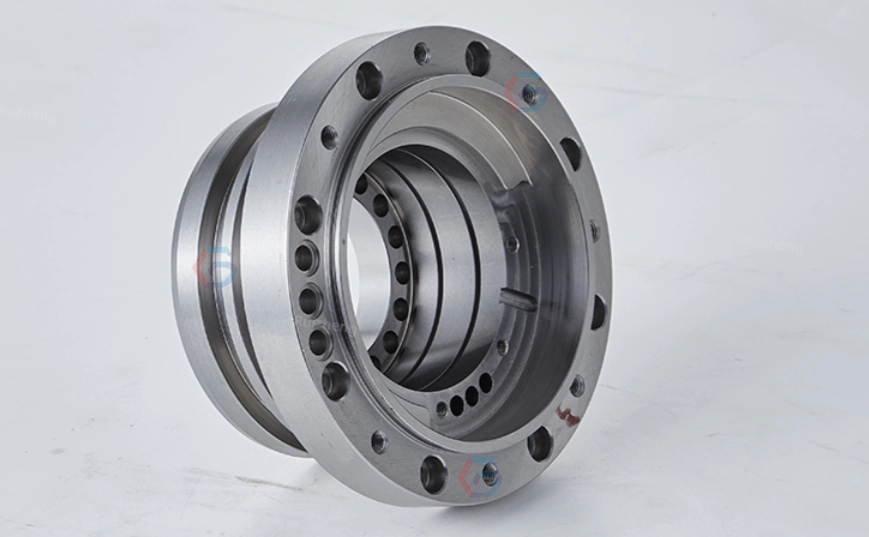

Flanged Bearing Housings

If your job needs wall or panel setup, mainly where side pulls are likely, flanged housings give strong hold and straight fit.

They appear in shapes like square, round, and oval flanges. This offers choices in how to attach and handle tight spaces.

Take-Up Bearing Units

Found mostly in conveyor systems, take-up units let you adjust shaft spots easily while running. This proves very useful where you need to handle belt pull or growth from heat on the fly.

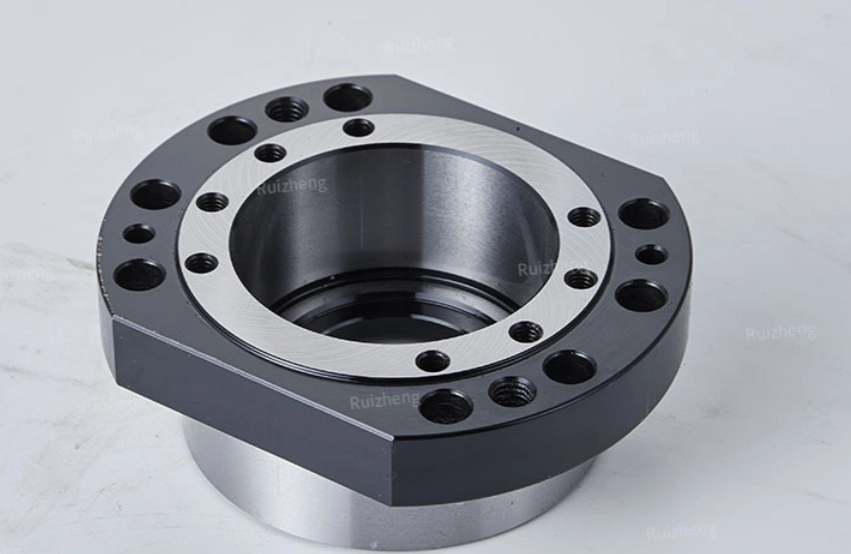

Cartridge Type Bearing Housings

Small but strong, cartridge housings suit spots with little room but no drop in output. They show up often in pump systems, fans, and tiny machine parts.

Pillow Block Bearing Housings

The go-to choice in the field. Their simple attach method and fit with many shaft sizes make them great for low to mid-weight jobs in everyday machines.

The Advantage of Custom Bearing Housing Solutions from Ruizheng

When ready-made parts fall short on the physical or setting challenges of your work, a built-to-fit method turns essential. For instance, in semiconductor cleanrooms or dusty factory areas, store-bought housings might lack enough seal strength or material toughness.

Be it a basic model or a special build, we offer full help from plan tweaks to final item handoff. That means no short cuts, only answers shaped to your tech needs and work aims. At Ruizheng, we focus on making sure each custom bearing housing fits your exact demands, drawing from years of hands-on know-how to deliver parts that stand up to real-world tests.

Key Benefits of Ruizheng’s Custom Bearing Housing Manufacturing

Tailored Engineering Support from Concept to Delivery

Each job starts with teamwork. You share your setup details. We add long years of cutting and shaping skills plus a focused group of experts who guide your idea into a real built item. We give quick check on plans and price quotes in under a day. We also back small test runs.

This close support means you get changes based on real feedback early on. Our team at Ruizheng listens to your goals and adjusts designs to match, ensuring the end product boosts your machine’s run time and cuts waste. From first sketch to final check, we keep you in the loop for smooth progress.

Advanced Materials and Coatings for Demanding Conditions

We work with tricky builds, exact join faces, and unique outer treatments like high-frequency quenching, nickel plating, or anodizing. These choices give top fight against rub, rust, shakes, or heat shifts.

By picking materials that match your setting, such as stainless steel for wet areas or alloys for high heat, we help your housings last longer. This not only saves money on fixes but also keeps your operations steady, even in harsh spots like chemical plants or outdoor setups.

Flexible Production Capabilities for Small to Large Volumes

With CNC turning, milling, grinding, and checks all in one place, we manage from single test pieces to big batch makes with the same speed. Fast reply: from plans to samples, the quickest ship is 7 days.

Our setup lets us scale up or down without losing quality. Whether you need just a few for a quick fix or hundreds for a full line, Ruizheng handles it all. This flexibility means less wait time for you and faster rollout of your projects.

Explore our custom bearing housing services to see how customization empowers precision.

How Ruizheng Ensures Quality in Every Housing Unit Delivered

Exact work does not happen by chance. It comes from careful steps in making.

Precision Manufacturing Processes That Drive Performance Gains

We run in a room with steady temps using top CNC tools, like five-axis centers with accuracy of ±0.003mm. We do checks during the build with auto tools.

The 0.002mm exactness and 0.001mm evenness make sure your bearing housings work well even under hard moving loads. This level of care means fewer surprises in your daily use, as each part fits just right and handles stress without fail. Our processes build in reliability from the start.

Rigorous Quality Control Protocols at Every Stage of Production

From shape and place checks (≤0.005mm) to hard checks (HRC rules), each piece faces many-step looks with German ZEISS coordinate measuring machines and Japanese Mitutoyo tools.

Full check of main sizes on 100% of items makes sure no flaws in each group. We track every step to spot issues early, so you receive parts that meet high marks right away. This thorough check builds trust in our work.

Application-Specific Design Optimization Improves ROI

Right fit not only lengthens bearing life but also drops machine noise and shakes. This leads to less stop time and fewer fix visits over the years.

It turns into clear cost cuts in your work and better return on your spend across the factory or machine row. By focusing on your needs, we help you get more value from each part, turning small tweaks into big wins for your bottom line.

Why Industry Leaders Choose Ruizheng as Their Partner in Motion Solutions

Selecting the best make partner is not just about what they can do. It is about feeling sure. When output counts most, buyers want providers who give full effort without cuts.

A Customer-Centric Approach That Prioritizes Your Success

You gain from quick talks all through the job life, from plan look to after-ship tech help. We back returns and swaps for quality problems and give flaw check reports. This secures your ongoing happiness.

Our focus stays on you, with clear updates and fixes to match your timeline. At Ruizheng, we see your wins as ours, so we go the extra step to make sure every delivery helps your goals.

Proven Track Record Across Diverse Industries

We aid buyers in fields like machine tools, compressors, semiconductors, industrial automation modules, robotic joints, hydraulic systems, packaging equipment, and more. Our group has won trust from world OEMs by giving solid parts that hit strict global rules, including ISO 9001 and SGS certifications.

From small shops to big plants, we have helped many succeed with parts that work without hitch. This wide reach shows our skill in tackling different challenges, making us a steady choice for your motion needs.

If you’re seeking consistent performance backed by unmatched technical execution—explore our range of custom solutions designed specifically for high-performance machinery.

Ready to Optimize Your Machinery with Custom Bearing Housings?

Let our engineers guide you to set up an answer that boosts trust while trimming run costs. Whether you build fresh gear or update old ones, we’ll aid you to hit top motion exactness with low life costs.

Our team stands ready to talk through your setup and suggest ways to make it better. With Ruizheng, you get not just parts, but a partner who cares about your full success. Reach out today to start seeing real gains in your operations.

Email: info@fsrzmachinery.com

Phone: +86 15875723726

Website: https://spindleshaft.com/

Let’s build precision together—your motion starts here.

FAQ

Q: Can you process non-standard designs for complex machinery setups?

A: Yes. We specialize in customized non-standard mechanical parts and can handle complex structures with high-precision mating surfaces and specialized coatings. Our process ensures these designs fit tight spots and tough jobs without issue.

Q: What industries do your bearing housings typically serve?

A: We supply bearing housings for machine tools, industrial robotics arms, packaging systems, semiconductors, compressors, pumps, linear modules, and similar equipment across manufacturing sectors. Each type gets tuned to the field’s unique pulls.

Q: How do you ensure accuracy during production?

A: We operate a temperature-controlled workshop equipped with CNC machining centers and use online inspection tools including German ZEISS CMMs to maintain tight tolerances up to 0.002mm with concentricity of 0.001mm. This setup keeps every part on point for your use.